Introduction to Steam Engines

How does a steam engine work? Steam engines captivated minds and powered the Industrial Revolution. They convert heat into motion using water and steam. These powerful machines began to change our world centuries ago. Today, they still intrigue us with their simplicity and efficiency. Understanding how a steam engine works reveals the genius of early engineering.

From locomotives to ships, steam engines drove transportation forward. They also powered factories, enabling mass production. This introduction to how a steam engine works will guide you through its core principles. Although less common now, their impact on technology and industrialization is undeniable. Let’s delve into the mechanics behind these fascinating machines.

History of Steam Engine Development

The development of steam engines marks a pivotal chapter in human history. The earliest known steam engine, the aeolipile, emerged in the 1st century AD. It was a toy, not a tool. However, its concept set the stage for future inventions. Fast forward to the 17th century, inventors began to harness steam for practical uses.

In 1698, Thomas Savery built the first commercial steam engine. It was a simple machine to pump water out of mines. Thomas Newcomen improved on this in 1712 with a piston system. His engine saw widespread use, especially in mining. But it was James Watt in the late 18th century who revolutionized steam engines. He introduced a separate condenser, making engines vastly more efficient.

Watt’s patents and improvements became the industry standard. His designs carried forward into the 19th century, pushing industry and transportation into a new era. Railways spread across the globe, and steamships crossed vast oceans, all powered by these engines.

The changes were monumental. Steam power not only mechanized production but also enhanced people’s mobility. By the 20th century, although overshadowed by electricity and combustion engines, the legacy of steam engines remained. Their influence in shaping the modern world is a reminder of their historic significance.

Fundamental Principles of Steam Engines

How does a steam engine work? Understanding the fundamental principles of steam engines is essential to grasp how they create motion. These engines operate on basic concepts of physics and thermodynamics. Let’s unpack these principles to see how steam engines convert heat into mechanical energy.

The Role of Heat and Steam

Heat is the starting point. It causes water to turn into steam, which expands greatly in volume. This expansion is powerful and can drive mechanical motion. A boiler heats the water to generate steam. The heat often comes from burning coal, wood, or oil.

Pressure and Expansion

The steam’s pressure is crucial. High pressure means more energy. When steam expands, it pushes against parts of the engine, like pistons. These parts then move and create mechanical work. The engine harnesses this pressure through precision-engineered components.

Condensation Process

After expansion, steam cools and condenses. It turns back into water. This change reduces pressure in the engine, allowing for a continuous cycle of operation. The condenser is a part that cools the steam and initiates this process.

By understanding how heat, pressure, and condensation work together, you can see why steam engines were so revolutionary. Their ability to harness steam’s energy made them the powerhouse of the Industrial Revolution.

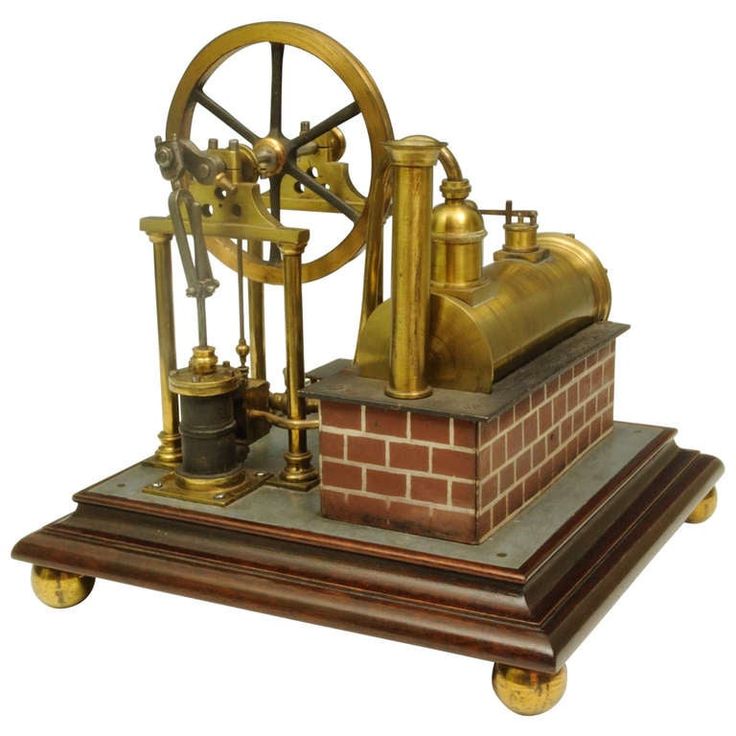

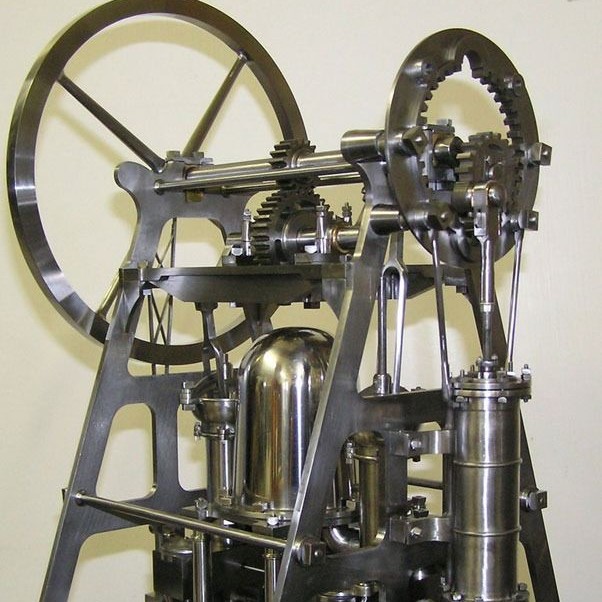

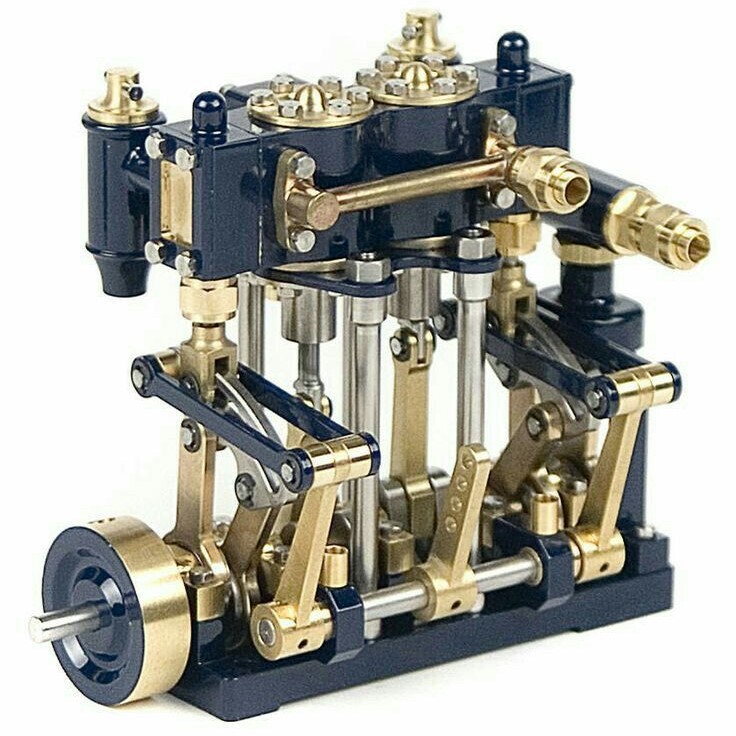

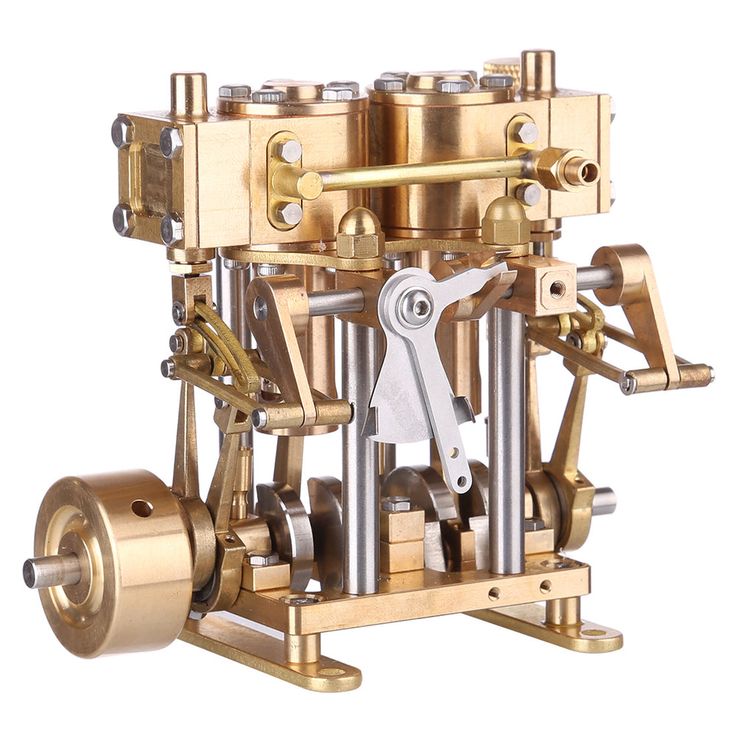

Key Components of a Steam Engine

There are several key components that work together to ensure the smooth operation of a steam engine. These parts are critical in transforming heat into mechanical energy. Let’s identify these components and understand their roles in the steam engine.

The Boiler

The boiler is where water turns into steam. It’s essentially a large tank that holds water and is heated by burning fuel. The fuel can be coal, oil, or wood. When the water heats up, it evaporates into steam.

Pistons and Cylinders

Pistons are housed within cylinders and move back and forth. The steam’s pressure pushes on the pistons, causing them to move. This motion turns into mechanical work, which can power machinery or even vehicles.

Steam Valves and Pipes

Valves control the steam flow, while pipes carry the steam to different parts of the engine. These components are crucial for directing steam accurately to ensure the engine runs properly.

The Condenser

The condenser plays a vital role after the steam does its work. Here, the steam cools and condenses back into water. This is essential for maintaining the engine’s pressure and allowing for the cycle to continue.

The Flywheel

A flywheel helps to smooth out the motion of the engine. It stores energy and provides a consistent rotational speed. This part is key to converting the back-and-forth motion of the pistons into usable rotational power.

By examining each component, we can see how a steam engine is a well-coordinated machine. Each part works in harmony to harness the energy of steam. Understanding these components and their functions is crucial to grasping how a steam engine works.

The Step-by-Step Operation of a Steam Engine

Understanding how a steam engine works is fascinating. The process is a step-by-step cycle that repeats. Here’s a simple breakdown of how a steam engine operates.

Heating of Water

- Fuel Source Utilization: The boiler heats water using various fuel sources such as coal, wood, or oil. Depending on the design and efficiency of the boiler, different fuel types can be utilized for effective heating.

- Heat Transfer Process: As fuel is combusted, it generates heat. This heat is conducted through the boiler walls, directly transferring energy to the water inside. This process raises the temperature of the water until it reaches its boiling point.

- Temperature Management: It is crucial to monitor the temperature during this phase to ensure the water reaches the optimal level for steam generation. Effective insulation and materials can help maximize heat retention.

Steam Formation

- Boiling Point Achievement: As the water heats up and reaches its boiling point, it begins to transform from a liquid state into steam. This phase change is crucial for the engine’s operation.

- Steam Production Rate: The more heat introduced into the boiler, the quicker the water will boil, thus generating steam at a faster rate. The steam produced is usually under high pressure, which is essential for driving the engine.

- Pressure Buildup: As the steam forms, it occupies a larger volume than the liquid water, leading to increased pressure within the boiler. This pressure is essential for the subsequent steps in the engine’s operation.

Release of Steam

- Controlled Release Mechanism: When the internal pressure of the steam reaches a specific threshold, safety mechanisms or valves allow the steam to escape into the cylinder. This release must be carefully controlled to maintain safe operational conditions.

- Pressure Utilization: The steam, now at high pressure, is directed into the engine cylinder where it exerts force on the piston. The efficiency of this process is vital for the overall performance of the engine.

- Power Generation: The force with which the steam enters the cylinder is what will ultimately drive the mechanical components of the engine. This power generation is the basis for the engine’s ability to perform work.

Piston Movement

- Transfer of Energy: The steam’s pressure pushes the piston back and forth within the cylinder. This movement is linear, converting the thermal energy of the steam into mechanical energy.

- Reciprocal Motion: As the piston moves in one direction, it creates a vacuum that allows more steam to enter from the boiler, continuing the cycle. This reciprocal motion is fundamental to the operation of steam engines.

- Mechanical Force Creation: The movement of the piston translates into mechanical force that can be harnessed to perform various types of work, making it a critical component of the steam engine.

Work Produced

- Energy Conversion: The kinetic energy generated from the piston’s motion is transferred to other mechanical components. This energy can be used to turn wheels, drive turbines, or operate machinery, depending on the design of the system.

- Output Measurement: The effectiveness of the engine can be measured in terms of the work output, which depends on the efficiency of the steam generation and lateral systems tied to the piston movement.

- Versatile Applications: The work produced by the piston can serve many purposes, from driving locomotives to powering factory machinery, showcasing the steam engine’s versatility in various industries.

Steam Condensation

- Cooling Process: After the steam has done its work, it is diverted into a condenser. In this stage, the steam cools down, losing thermal energy and transitioning back into a liquid state through condensation.

- Heat Exchange Mechanism: The condenser uses water or air to absorb the excess heat from the steam. This heat exchange process is essential to maintain the cycle’s efficiency.

- Water Recovery: The cooled and condensed steam collects as water in the condenser, ready to be cycled back into the boiler for heating again. This process is vital for the closed-loop system of steam engines.

Water Recycled

- Reintroduction into the Boiler: The condensed water is pumped back to the boiler, where it is reheated by the combustion of fuel. This reintroduction is crucial for sustaining the continuous operation of the steam system.

- Starting the Cycle Anew: The cycle of heating, steam forming, releasing into the piston, and condensing begins again, allowing for uninterrupted energy generation.

- System Efficiency: Successfully recycling water in the system minimizes waste and maximizes efficiency, reducing the need for constant new water supply and contributing to environmental sustainability.

This cycle can happen many times per minute. It creates a constant power source for heavy work. Steam engines were game-changers back in their day. Even in modern times, understanding this process gives insight into early industrial technology.

Variations of Steam Engines and Their Uses

Steam engines have evolved over time, and with evolution comes variation. Different types of steam engines serve diverse purposes. Here, we explore the main variations and their applications.

Stationary Steam Engines

These are large engines fixed in one place. They powered factories and mills during the Industrial Revolution. They run machinery such as pumps, looms, and hoists. Their size and power made them ideal for heavy and steady tasks.

Portable Steam Engines

Unlike stationary ones, these engines are movable. They were used on farms for tasks like threshing or plowing. They often featured wheels and frames for easy transport. Farmers favored them for their versatility and convenience.

Locomotive Engines

These are specifically designed for transportation. They pull trains along railroads. Locomotives gained fame for shrinking travel times across countries. They were a symbol of speed and progress in the 19th century.

Marine Engines

Marine engines powered steamboats and ships. These engines enabled crossing oceans and exploring new lands. They differ in design, tailored to navigate the high seas and withstand marine conditions.

Traction Engines

Traction engines are a cross between portable and locomotive engines. They move on wheels and often pull heavy loads. These were common in road construction and hauling heavy equipment.

Each variation of the steam engine has played a role in shaping today’s world. From factories to farms, and from railways to the high seas, these engines had widespread uses. Knowing the types helps appreciate their impact on development and industry.

Modern Applications of Steam Engine Technology

Although not as prevalent as they were during the Industrial Revolution, steam engines still have modern applications. Their basic operational principles of heat exchange and mechanical energy conversion remain relevant in specific industries.

Power Generation

In power plants, steam turbines—which are modern descendants of the steam engine—play a crucial role. They generate electricity by using steam to turn large turbines connected to generators. These turbines are highly efficient and can handle vast amounts of steam at high pressure, making them suitable for large-scale power production.

Heritage Railways

Heritage and tourist railways continue to use steam locomotives. These trains are a living history, showcasing how steam power revolutionized transportation. They provide unique experiences, transporting passengers back in time to the age of steam.

Educational Demonstrations

Steam engines are often used for educational purposes. Science museums and educational institutions may operate steam engines to demonstrate the mechanics of heat, steam, and motion. They serve as practical examples of thermodynamics and engineering principles.

Industrial Processes

A few industries might still use steam engines, especially where the infrastructure has been set up for it, and there’s no need for high-speed operation. For instance, in sugar mills or sawmills, steam power can still be an effective means to drive machinery.

Research and Development

Modern engineers and researchers sometimes turn to steam technology for inspiration. Focus on renewable energy sources, like geothermal or solar-generated steam, has brought renewed interest in the efficiency and potential of steam engine technology.

While steam engines are no longer the driving force of industry they once were, these modern applications highlight the lasting legacy and ongoing potential of steam technology. Each use underscores an enduring fascination with the way heat and steam can be harnessed to do work.

Challenges and Innovations in Steam Engine Design

While the golden age of steam engines has passed, challenges in their design have spurred innovations even today. Below are key points of interest in the realm of steam engine technology:

- Efficiency Improvements: Contemporary steam engines strive for better fuel efficiency. Research focuses on minimizing heat loss and maximizing output.

- Material Advances: Modern materials can withstand higher temperatures and pressures. This allows for engines that are both safer and more powerful.

- Environmental Considerations: There’s a push to make steam engines eco-friendlier. Finding ways to lower emissions while using renewable energy sources is a priority.

- Size Reduction: Engineers have been working to make steam engines smaller and more compact. This helps in using them in places where space is at a premium.

- Control Systems: Modern control technology aids in the precise operation of steam engines. This has led to automation and better performance.

- Restoration Projects: Many see historical value in old steam engines. Restoring them often uncovers challenges that lead to new methods and practices.

Through these challenges and innovations, steam engine design continues to evolve. It finds new life in various applications and remains an important part of our industrial heritage. The keywords ‘how does a steam engine work’ touch on the essence of this progress, hinting that the quest for understanding and improvement is ever ongoing.