Introduction to Jet Engines

Jet engines are a marvel of modern engineering. How does a jet engine work? Simply put, they propel aircraft through the air at high speeds. These engines harness the principles of thrust and Newton’s third law. For every action, there is an equal and opposite reaction. A jet engine sucks air in, compresses it, adds fuel, and ignites the mixture. This produces a high-speed exhaust, propelling the engine forward. The concept seems straightforward, but the mechanics are complex. Jet engines come in many types. There are turbojets, turbofans, turboprops, and more.

Each design serves a different purpose in aviation. Jet engines are not only for airplanes. They also power helicopters, boats, and even cars. In this article, we will explore how does a jet engine work. We will look at the operation principles and key components. From air intake to generating thrust, we will cover it all. So, get ready to dive into the fascinating world of jet engines!

Principles of Jet Engine Operation

The operation of a jet engine is predicated on a simple concept: thrust generation. This seemingly simple process involves several steps, each crucial to the engine’s overall function. First, air is taken into the engine. Then, it’s compressed to higher pressure levels, which is essential for efficient combustion. Fuel is then injected into the compressed air and ignited. The resulting high-speed exhaust gases are what propel the engine forward.

These steps occur in rapid succession and depend on precision-engineered components working in harmony. The amount of thrust produced can be adjusted by controlling the air intake, the fuel-to-air ratio, and the speed at which the mixture is ignited and expelled.

Throughout this process, the jet engine operates under the fundamental laws of physics. Most notably, Newton’s third law about action and reaction plays a key role. When the engine expels exhaust gases backward at high speed, the reaction pushes the engine, and thus the aircraft, forward. This is how the core principle of how a jet engine works is translated into the speedy propulsion of various types of aircraft.

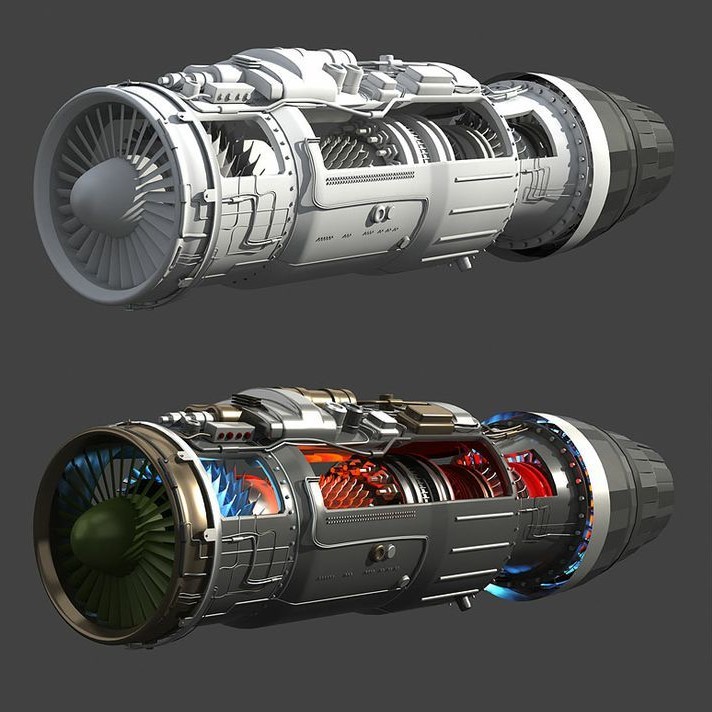

Key Components of a Jet Engine

Jet engines are intricate machines composed of several critical parts that work together seamlessly to generate thrust. Understanding the functions of these components is essential for grasping the overall workings of a jet engine. Let’s take a closer look at each key element and see how they contribute to the engine’s operation.

Air Intake

- Initiation of the Process: The journey begins at the air intake, often referred to as the “mouth” of the jet engine. It plays a vital role in the entire operation.

- Airflow Control: The intake is designed to facilitate the steady flow of air into the engine. Proper airflow is crucial for maintaining the efficiency of the engine.

- Aerodynamic Design: The shape of the air intake is typically streamlined to reduce drag, allowing for optimal air entry. This aerodynamic design minimizes turbulence, ensuring that the air enters smoothly and efficiently.

- Temperature and Pressure Management: As air enters, its temperature and pressure are critical factors. The intake helps manage these conditions to prepare air for the compression stage.

Compressor

- Functionality: After the air intake, the airflow moves to the compressor, a key component whose primary role is to increase the pressure of the incoming air.

- Mechanism of Compression: The compressor works by squeezing the air into a smaller space. It typically contains several rotating blades that spin at high speeds, compressing the air as it moves through.

- Benefits of High Pressure: By increasing the air pressure, the compressor makes it easier for this high-pressure air to mix effectively with the fuel, facilitating better combustion.

- Types of Compressors: There are different types of compressors in jet engines, including axial and centrifugal compressors. Each design has its own advantages based on specific performance requirements.

Combustion Chamber

- Ignition and Energy Release: Once the air is compressed, it enters the combustion chamber. This is where the magic happens; fuel is introduced and ignited, creating a rapid combustion reaction.

- Mixture of Air and Fuel: In the combustion chamber, the high-pressure air mixes with fuel. The even mixing of these components is essential for efficient burning.

- Production of Energy: The combustion process generates enormous amounts of energy in the form of hot gases. This energy is what drives the rest of the engine and ultimately propels the aircraft.

- Control of Combustion: The combustion chamber designe with specific shapes and materials to withstand high pressures and temperatures during the burning process, ensuring safety and efficiency.

Turbine

- Energy Conversion: The turbine is next in line, where it captures the energy produced from the burning gases in the combustion chamber. This energy is vital for powering the compressor and maintaining the engine’s operation.

- Mechanical Connection to the Compressor: The turbine is directly connected to the compressor via a shaft. As the hot gases spin the turbine blades, the mechanical energy generated is used to keep the compressor running.

- Functionality Comparison: The turbine operates similarly to a windmill, with the combustion gases acting as the wind that spins the turbine blades. This continuous energy cycle is crucial for extending the engine’s operation.

- Efficiency and Performance: An efficient turbine designe to maximize energy extraction from the exhaust gases, which enhances the overall performance of the jet engine.

Exhaust Nozzle

- Final Stage of Gas Expansion: The exhaust nozzle is the last major component of a jet engine, where the hot gases expel from the engine. This stage is critical for generating thrust.

- High-Speed Gas Escape: As the gases exit through the exhaust nozzle, they do so at remarkably high speeds. This rapid expulsion creates a push against the engine, propelling the aircraft forward.

- Design for Thrust Generation: Exhaust nozzles designe to accelerate the gas flow, optimizing thrust production. Different nozzle designs can also affect engine performance characteristics.

-

Impact on Aerodynamics: The shape and size of the exhaust nozzle can significantly influence the aircraft’s aerodynamics and overall flight efficiency, making it a vital consideration in jet engine design.

The Process of Air Intake and Compression

Understanding the process of air intake and compression is crucial when exploring how does a jet engine work. Here’s a breakdown of this phase:

Air Intake: The Beginning

It all starts at the air intake. The intake acts like the engine’s mouth, gulping in ambient air. The design of the intake is vital; it must capture air efficiently to ensure a steady supply to the compressor. Think of it as breathing in before a workout; getting enough air is key.

Compression Stages:

After the initial breath, the compressor takes over. Usually, this component has multiple stages. Each stage squeezes the air more until it’s at a much higher pressure. This step is crucial. Why? Because compressing the air increases its energy potential, making it ready for the next big step – combustion. Compressed air has the power needed to mix properly with fuel and burn effectively.

End Goal of Compression:

The aim of compression is two-fold. Firstly, it ensures that the air is packed tight with energy. Secondly, it raises the air to a temperature that is optimal for burning fuel. High-pressure, high-temperature air is the best recipe for an efficient combustion process. Remember, the better the compression, the more powerful the engine can be.

The harmony between the air intake and the compressor is fundamental to a jet engine’s effective operation. It prepares the stage for the exciting process of fuel injection and combustion, which is up next in our journey through jet engine mechanics.

Fuel Injection and Combustion

Moving from compressed air, we enter the stage of fuel injection and combustion. Here’s how this pivotal phase in the operation of a jet engine unfolds:

Fuel is Injected:

Once the air is compressed to the right level, it flows into the combustion chamber. Here, fuel injectors spray fuel into the highly pressured air. Precision is key. The right amount of fuel must mix with air to ensure efficient burning.

Ignition Occurs:

With fuel and compressed air blended, they ignite. The ignition happens in the combustion chamber, generating immense heat and expanding gases.

Energy Release:

Compressed air and fuel, now ignited, create a rapid expansion of gases. This releases energy needed to turn the turbine and propel the aircraft.

Continuous Process:

Remember, this all happens in a continuous loop. As fuel burns, it keeps the turbine spinning, which, in turn, keeps the compressor working. It’s a self-sustaining cycle that ensures the jet engine operates smoothly.

The science behind fuel injection and combustion is simple yet powerful. Perfect the mix and timing, and the jet engine performs at its peak. This phase dictates the might of the engine, paving the way for the thrust that moves aircraft through the skies.

How Thrust is Generated

Generating thrust is the essence of how does a jet engine work. To understand this, let’s explore the final stages of jet engine operation.

Expanding Gases Push Against Turbine:

Once combustion occurs, the hot, expanding gases exert force on the turbine blades. This turns the turbine.

Turbine Rotates Compressor:

As the turbine spins, it also rotates the compressor attached to it. This ensures continuous air intake and compression.

Gases Exit Through Nozzle:

After turning the turbine, gases rush out through the exhaust nozzle.

Thrust is Produced:

By exiting forcefully, these gases push the engine in the opposite direction, creating thrust.

Control of Thrust:

Pilots adjust thrust by modifying fuel flow and compressor speed to control the aircraft’s speed.

The process is a precise dance of components. Engineering ensures that each step, from air intake to exhaust expulsion, contributes to an efficient thrust generation. It’s the rapid ejection of gases that sends aircraft skyward, demonstrating Newton’s third law in glorious action.

Jet Engine Efficiency and Performance

With the key components and processes of jet engine operation explained, let’s turn to efficiency and performance. These aspects are essential for understanding how does a jet engine work to its fullest potential.

Optimizing Fuel Usage:

Efficiency in a jet engine is largely about fuel economy. The goal is to get the maximum thrust with the least amount of fuel. Engineers work to perfect the air-to-fuel ratio for optimal burning, reducing waste.

Minimizing Drag:

Performance also hinges on reducing aerodynamic drag. The design of the engine and aircraft plays a big role. Streamlined shapes help the aircraft cut through the air smoothly.

Enhancing Durability:

A well-performing jet engine isn’t just powerful; it’s also durable. It must withstand high temperatures and pressures over time. Using advanced materials is key to engine longevity.

Regular Maintenance:

Keeping jet engines in top condition is crucial for performance. Regular check-ups and maintenance prevent wear and tear from compromising engine efficiency.

Innovative Cooling Techniques:

Effective cooling systems protect the engine’s components. This preservation of the turbine and other parts ensures continuous high performance.

Efficiency and performance go hand-in-hand in jet engine mechanics. Through careful design, constant refinement, and maintenance, these engines work reliably, powering flights across the globe.

Advances in Jet Engine Technology

In recent years, jet engine technology has seen remarkable advancements. These improvements aim to boost performance, enhance fuel efficiency, and reduce environmental impact. Let’s explore some of the cutting-edge developments in this field:

Material Innovations:

Engineers have introduced new materials, like ceramic matrix composites (CMCs). CMCs withstand higher temperatures and weigh less than traditional materials. This change leads to engines that are not just more efficient but also less taxing on the aircraft structures.

3D Printing:

3D printing technology, also known as additive manufacturing, plays a significant role. It allows for complex parts production with reduced weight and waste. This precision contributes to both engine performance and sustainability.

Advanced Combustion Systems:

New combustion system designs optimize fuel burning. They reduce emissions such as nitrogen oxides (NOx), which are harmful to the environment. These systems ensure that jet engines are not only powerful but also cleaner.

Computerized Monitoring:

Modern engines come equipped with sophisticated computer systems. These systems monitor engine health in real-time, predicting maintenance needs. Such proactive measures save time and resources while ensuring safety.

Improved Aerodynamics:

Engine and aircraft designs with better aerodynamics decrease drag. Lower drag means that engines don’t have to work as hard, improving fuel economy. It also enhances the plane’s overall performance.

Noise Reduction Techniques:

Researchers are developing ways to make jet engines quieter. Noise reduction is crucial around airports to lessen the impact on nearby communities. Quieter engines mean a more pleasant experience for passengers as well.

These technological advances represent how the industry is evolving. The focus is on creating engines that are not only more efficient and powerful but also more environmentally aware and user-friendly. The goal is clear: make jet engines that pave the way for a new era in aviation.

Conclusion: The Fascinating Mechanics of Jet Engines

How does a jet engine work? Understanding the workings of jet engines unveils the fascinating mechanics behind aviation technology. From air intake to high-speed exhaust, each component plays a crucial role in achieving efficient propulsion. As advancements continue in jet engine design, we can expect to witness even more remarkable innovations in flight technology.

By breaking down the complexities of jet engines into simplified mechanics, enthusiasts can appreciate the science behind aviation. Whether you are a casual observer or a dedicated aviation enthusiast, grasping the principles of jet propulsion is essential for understanding how aircraft navigate the skies. As we look to the future, the evolution of jet engines will surely enable more efficient and sustainable air travel, transforming the landscape of aviation continually.