The 6.7 Cummins engine is a renowned powerhouse often found in heavy-duty trucks, agricultural machinery, and various industrial applications. This engine’s performance is boosted significantly by its turbocharger, enhancing power output and fuel efficiency. Understanding the 6.7 Cummins turbo diagram is crucial for troubleshooting any issues related to the turbo system. In this article, we will delve into the components of the turbo system, how to interpret the diagram, common problems, and effective troubleshooting techniques. This will serve as a useful guide for mechanics and owners alike, ensuring your relationship with the 6.7 Cummins turbo diagram engine remains productive.

Overview of the 6.7 Cummins Engine

A Powerful Engine for Tough Jobs

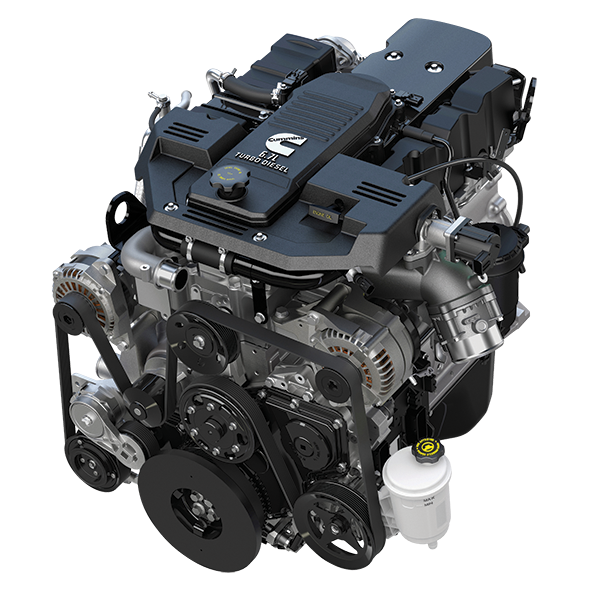

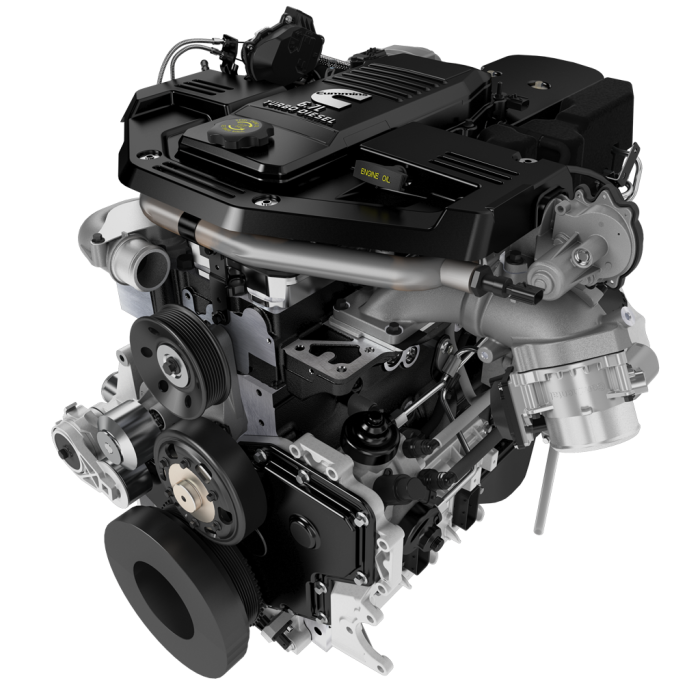

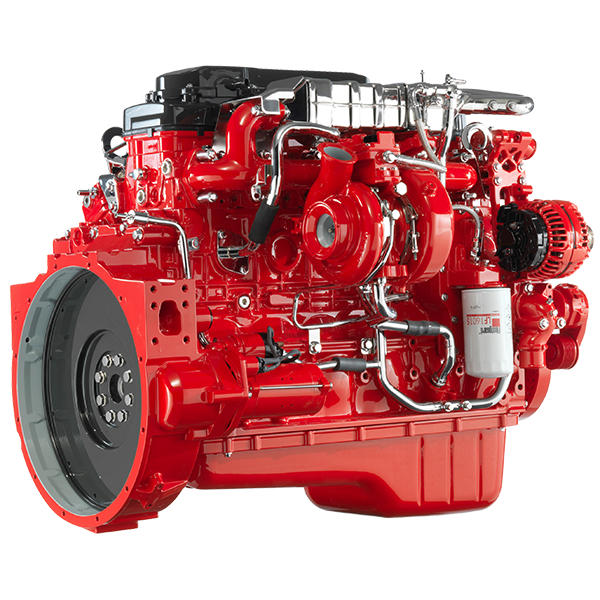

The 6.7 Cummins engine is well-known for its durability and reliability. It is commonly used in heavy-duty trucks such as the Ram 2500 and 3500 models. With its 6.7-liter inline-six design, this engine has become a favorite among enthusiasts who appreciate its robustness and impressive torque output. The combination of turbocharging and direct fuel injection allows for enhanced performance, making it suitable for demanding applications. Therefore, regular maintenance and a clear understanding of the engine’s components, especially the turbocharger, are critical.

The Role of the Turbocharger

At the heart of the 6.7 Cummins turbo diagram’ performance is the turbocharger. This component compresses incoming air, allowing the engine to burn fuel more efficiently and produce more power. The turbocharger draws exhaust gases from the engine to spin a turbine, which then pressurizes the intake air. This process efficiently increases engine responsiveness and improves torque production, especially in challenging driving conditions. Understanding how the turbocharger works is essential for diagnosing performance issues and ensuring optimal engine operation.

Significance of the Turbo Diagram

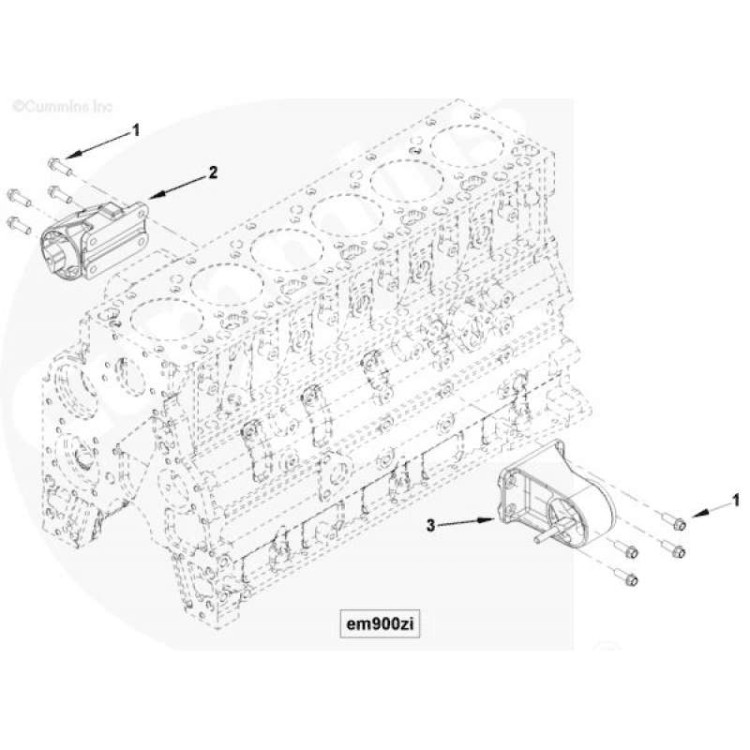

A well-organized turbo diagram serves as a valuable reference. It illustrates the various components and connections in the turbo system, providing a clear view of how everything works together. Knowing how to read and interpret this diagram can help identify potential problems more effectively. This understanding is particularly vital when troubleshooting issues that impact performance or reliability, as many components are interconnected.

Components of the Turbo System

Turbocharger Assembly

The turbocharger assembly is composed of several key components, each contributing to its functionality. The main parts include the compressor housing, turbine housing, turbine wheel, and compressor wheel. The turbine wheel connects to the exhaust side, which drives the turbo, while the compressor wheel pressurizes the incoming air. This dynamic interaction between the two components allows for optimal power generation. Understanding each part’s function is essential when diagnosing issues or making modifications.

Wastegate Mechanism

The wastegate is a critical component within the turbo system, regulating boost pressure. It opens to divert exhaust gases away from the turbine wheel when a predetermined boost pressure is reached. This action prevents overboost, which could cause engine damage or performance issues. There are typically two types of wastegates in turbo systems: internal and external. Internal wastegates are mounted within the turbo assembly, while external wastegates are separate components. Understanding how the wastegate operates helps in troubleshooting boost-related issues.

Intercooler and Piping

The intercooler plays an essential role by cooling the compressed air from the turbocharger before it enters the engine. Hot, compressed air is less dense, leading to reduced engine efficiency. By lowering the air temperature, the intercooler increases the air’s density, allowing for improved combustion and more power. Additionally, the piping that connects these components influences airflow and performance. Any leaks or obstructions in the piping can lead to a loss of boost pressure, significantly affecting engine performance.

Reading the Turbo Diagram

Understanding the Layout

The turbo diagram provides a visual representation of the components and their connections within the system. Familiarizing yourself with the layout is critical for troubleshooting. The diagram typically labels each component clearly, showing how they interconnect by lines representing hoses and pathways. Understanding these connections allows for better insights into how air and exhaust flow through the system, aiding effective troubleshooting processes.

Identifying Components

When analyzing the turbo diagram, identify essential components like the turbocharger, intercooler, wastegate, and associated piping. Take note of the location of sensors, such as the turbo pressure sensor, which provides feedback to the engine control unit (ECU). Knowing where each component is located helps in both inspection and repair efforts. This understanding becomes particularly important when diagnosing performance issues or planning modifications.

Flow Paths of Air and Exhaust

The turbo diagram will often illustrate the flow paths of air and exhaust gases. Follow these paths as you study the diagram. Understanding how air moves from the air intake, through the turbocharger and intercooler, and finally into the engine’s intake manifold is vital. Conversely, monitoring the flow of exhaust gases from the engine to the turbocharger will provide insights into the overall efficiency of the system. Identifying blockages or restrictions along these paths can help pinpoint areas that may require attention.

Common Turbo Problems and Symptoms

Boost Pressure Issues

One of the most common problems encountered with turbo systems is issues related to boost pressure. Symptoms may include a noticeable loss of power during acceleration or difficulty maintaining speed on inclines. If you are experiencing these symptoms, it could indicate a malfunction in the wastegate or a leak in the piping. Checking the boost pressure using a gauge can provide valuable data to confirm suspicions regarding performance issues.

Oil Leaks

Turbochargers are subjected to high temperatures and pressures, making them susceptible to oil leaks. These leaks can manifest as excessive smoking from the exhaust or oil puddles beneath the vehicle. If you notice either of these signs, it’s essential to inspect the turbocharger and its seals. Addressing oil leaks promptly can prevent further damage to the turbo system. Regular maintenance, including oil changes and inspections, can also reduce the risk of leaks developing over time.

Whistling or Unusual Noises

Unusual noises, such as whistling or grinding, can indicate potential issues within the turbocharger. A whistling sound may suggest a leak in the intake side, while grinding could indicate damage to the turbine or bearings. These noises should not be ignored, as they can lead to significant engine problems if not addressed quickly. It is wise to consult the turbo diagram to trace the source of the noise and take necessary action to correct the issue.

Effective Troubleshooting Techniques

Visual Inspection

Conducting a thorough visual inspection is often the first step in troubleshooting turbo problems. Check the turbocharger for any signs of physical damage or excessive wear. Inspect the piping for cracks, loose connections, or signs of oil leakage. Assess the condition of the wastegate to ensure it is functioning correctly. A careful examination can reveal obvious issues that require immediate attention and can help guide further troubleshooting efforts.

Utilizing Diagnostic Tools

Using diagnostic tools can help pinpoint issues more accurately. Boost pressure gauges can track performance issues, while an OBD-II scanner can provide valuable information regarding engine performance and error codes. This data will help identify any underlying problems that may not be immediately visible. If the vehicle is equipped with a turbo pressure sensor, ensure it is functioning correctly and transmitting accurate readings to the ECU.

Consulting Professional Help

If troubleshooting efforts do not yield results, consider seeking professional help. Experienced mechanics can offer insights and expertise when diagnosing turbo issues. They have specialized tools and experience that can facilitate a more thorough inspection and more complex troubleshooting. Moreover, they can provide advice on any necessary repairs or upgrades that can enhance the efficiency and longevity of your turbocharger.

Maintaining Your Turbo System

Regular Maintenance Checks

Regular maintenance checks are essential for ensuring the longevity and performance of your turbo system. Schedule periodic inspections to assess the condition of all components. Pay special attention to oil levels, as adequate lubrication is critical for a properly functioning turbocharger. Check for oil and coolant leaks, and monitor any unusual noises during operation. Performing routine checks allows you to identify and address issues before they escalate into costly repairs.

Keeping the Air Filters Clean

Clean air filters are important for the efficient operation of your turbo system. Clogged or dirty air filters can restrict airflow, reducing the performance of the turbocharger. Make it a habit to inspect and clean or replace air filters regularly. This simple maintenance task can make a significant difference in the overall efficiency and performance of your engine. Additionally, clean filters enhance fuel efficiency and improve engine responsiveness.

Keeping the System Cool

Heat management is crucial for the longevity of your turbocharger. Ensure that the cooling system is functioning correctly and that the coolant levels are adequate. If you are working in extreme conditions, consider using a higher-quality coolant designed to withstand higher temperatures. Turbochargers generate significant heat during operation, and maintaining effective cooling can help prevent damage and ensure optimal performance.

Conclusion

Understanding the workings of the 6.7 cummins cooling system diagram is essential for any vehicle owner or mechanic. Familiarity with the turbo diagram, coupled with knowledge of common issues and effective troubleshooting techniques, can empower you to keep your vehicle in peak condition. By focusing on proper maintenance, regular checks, and using the right tools, you can ensure that your turbocharger performs at its best. Whether you’re a seasoned mechanic or a dedicated DIY enthusiast, taking the time to understand your system will lead to improved performance and fewer issues down the road. Investing in knowledge and maintenance can make all the difference, ensuring that your 6.7 Cummins turbo diagram system continues to deliver the power you expect.