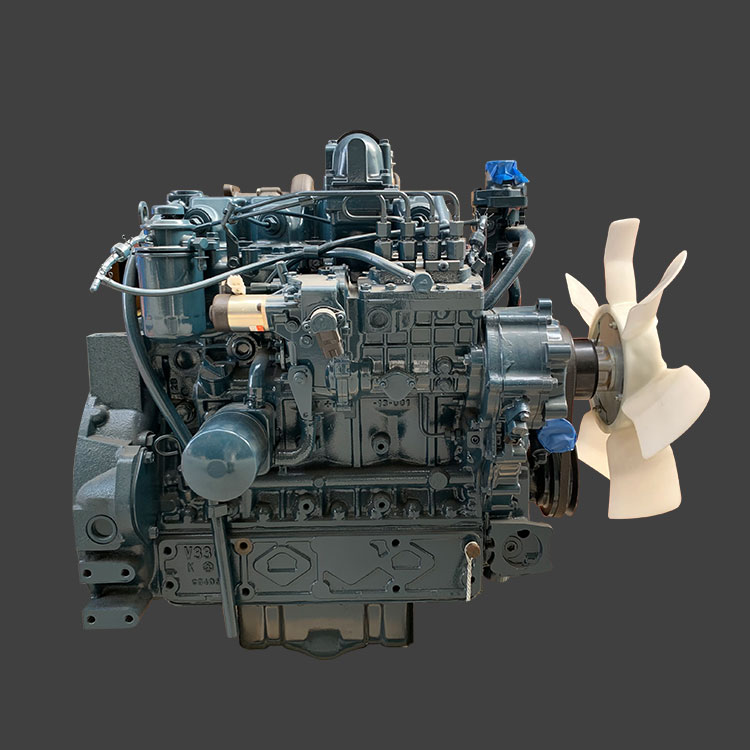

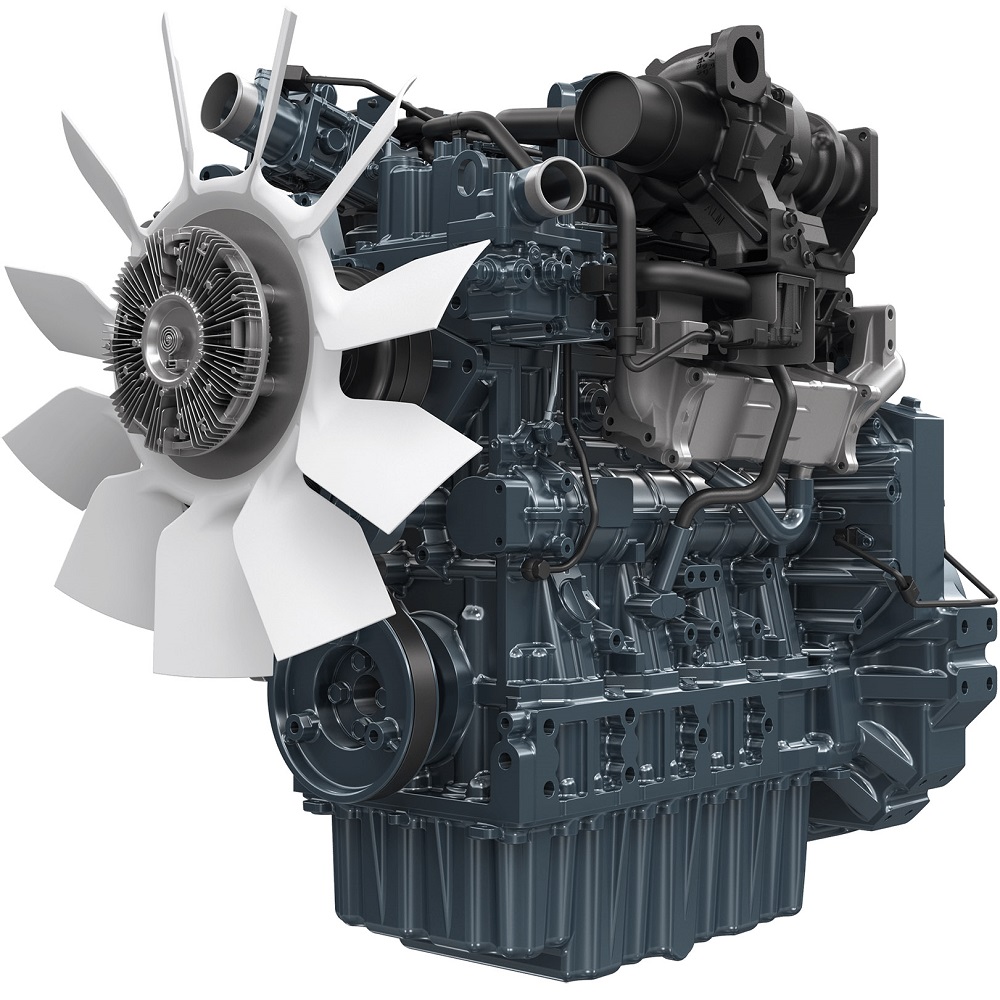

Kubota engines are renowned for their power, durability, and efficiency. Used widely in agriculture, construction, and various industrial applications, these engines represent a significant investment for many businesses and individuals. Proper maintenance is crucial to maximizing the lifespan and performance of a Kubota engine. By following some essential guidelines and best practices, you can ensure that your engine continues to operate at its optimal efficiency for years to come. This article will explore key maintenance tips for Kubota engines parts, highlighting aspects such as routine checks, fluid management, and preventative measures.

Understanding the Importance of Maintenance

Enhancing Engine Longevity

Regular maintenance is fundamental to extending the lifespan of your Kubota engine. Just like any other machine, wear and tear can take a toll over time. Without proper care, components can become damaged or fail, leading to costly repairs and decreased functionality. By adhering to a structured maintenance schedule, you can mitigate issues before they escalate and ensure that your engine operates smoothly.

Improving Fuel Efficiency

A well-maintained engine runs more efficiently, resulting in better fuel economy. With proper care, a Kubota engine can perform its tasks while consuming less fuel, ultimately saving you money in the long run. Regularly checking for issues such as clogged filters or worn-out parts can help maintain optimal fuel efficiency. Achieving this efficiency is particularly important in commercial applications where fuel costs can significantly impact overall profitability.

Complying with Warranty Requirements

For many users, abiding by maintenance protocols is also essential for warranty compliance. Most manufacturers require regular maintenance to keep warranties valid. Neglecting necessary upkeep could void your warranty and leave you to shoulder repair costs entirely. By following Kubota’s recommendations and keeping records of maintenance activities, you safeguard your investment and ensure that you receive necessary support from the manufacturer.

Routine Maintenance Checks

Daily Inspections

Conducting daily inspections before operating your Kubota engine is crucial to spot potential issues. Check the engine oil level, coolant status, and fuel levels to ensure they are at appropriate levels. Additionally, inspect belts and hoses for any signs of wear or damage. A thorough pre-operation check can help identify problems that could worsen during operation and potentially lead to engine failure.

Weekly Maintenance Tasks

On a weekly basis, more comprehensive checks should be performed. This includes inspecting filters and cleaning or replacing them as needed. Air filters, in particular, can become clogged with dirt and debris, affecting engine performance. Regularly cleaning or replacing these filters ensures that the engine receives proper airflow and contributes to optimal performance. Furthermore, checking fluids such as hydraulic oil and transmission fluid can help maintain overall engine health.

Seasonal Maintenance

As seasons change, so do the maintenance requirements for your Kubota engine. At the beginning of each season, it’s a good practice to evaluate the engine’s performance and overall condition. Inspect the coolant system for leaks and ensure that the coolant levels are adequate. Additionally, consider checking the battery and electrical systems, especially if the engine has been idle for an extended period. Seasonal maintenance will prepare your engine for the demands of different operating conditions.

Engine Fluid Management

Importance of Quality Fluids

Using the right fluids is essential for the effective functioning of Kubota engines. Engine oil, coolant, hydraulic fluid, and fuel should all meet Kubota’s specifications to ensure optimal performance. High-quality fluids provide better lubrication, reduce friction, and enhance cooling capabilities. Using subpar fluids can lead to increased wear and tear, reduced performance, and various operational issues.

Regular Oil Changes

Regular oil changes are one of the most critical aspects of engine maintenance. As the engine runs, oil breaks down and becomes contaminated with particulates, reducing its effectiveness. Changing the oil according to the manufacturer’s recommendations is vital for maintaining engine health. For many Kubota engines, the suggested oil change interval is every 200 hours of operation. Keeping a log of oil changes can help you adhere to this schedule.

Cooling System Care

Maintaining the cooling system is essential for preventing overheating. Inspecting coolant levels and quality regularly ensures that the engine can operate efficiently. Always use the recommended coolant type for your Kubota engine. Over time, coolant can become acidic, which can corrode internal components. Flushing the cooling system and replacing coolant as needed protects your engine from potential damage.

Cleaning and Maintenance Techniques

Regular Cleaning

Keeping your Kubota engine clean is crucial for its longevity. Dust, dirt, and debris can accumulate on various engine surfaces, reducing efficiency and leading to overheating. Regularly cleaning the exterior of the engine helps you monitor potential leaks or issues. Use a damp cloth to wipe surfaces, and if necessary, employ a pressure washer with care to remove stubborn grime.

Addressing Clogged Filters

Filters play a critical role in maintaining the engine’s performance. Dirty or clogged filters can hinder airflow and contaminate fluids. It’s essential to check air, oil, and fuel filters regularly for signs of blockage. Replace filters that show significant buildup or have been in use longer than the recommended interval. This simple act can help prevent more severe engine issues.

Inspecting Belts and Hoses

Belts and hoses are crucial components that require regular inspection. They can wear out over time and may crack, fray, or develop leaks. Regularly check the condition of belts and hoses, looking for signs of wear. Replace any components that appear damaged to avoid breakdowns during operation. Taking this precaution can provide peace of mind when using your Kubota engine for demanding tasks.

Troubleshooting Common Issues

Recognizing Symptoms of Trouble

Understanding the common signs of engine trouble can help prevent minor issues from becoming major problems. Look for unusual noises or vibrations during operation, as these can indicate faulty components. Warning lights on the dashboard should not be ignored. If you notice any unusual behavior from your Kubota engine, consult the owner’s manual for troubleshooting steps, or seek assistance from a qualified technician.

Addressing Overheating

Overheating is a common problem that can lead to significant engine damage if not addressed promptly. If the engine temperature gauge indicates a rise, take immediate action. Turn off the engine and allow it to cool down. Check the coolant level and look for leaks in the cooling system. Addressing overheating issues quickly can save you from costly repairs and prolong the life of your engine.

Dealing with Fuel Problems

Fuel-related issues can also affect your Kubota engine’s performance. Should you experience difficulty starting or poor idling, check the fuel filter for clogs and examine the fuel quality. If you suspect water contamination, consider draining the tank and replacing the fuel. Regular fueling practices can help prevent such problems, ensuring that your engine runs smoothly and efficiently.

Preparing for Seasonal Changes

Adjusting to Different Operating Conditions

Seasonal changes bring various challenges for engine performance. Before the onset of hot or cold seasons, prepare your engine for the weather conditions. In winter, consider using engine block heaters to ensure easy starts, and keep the oil warm. For summer, ensure optimal cooling capabilities by checking the radiator and coolant levels. Proper preparation is critical for ensuring reliable performance year-round.

Storing the Engine

If you plan to store your Kubota engine for an extended period, proper care is essential. Clean the exterior and perform all necessary maintenance before storage. Protect the engine from moisture and potential corrosion by storing it in a dry, sheltered location. If applicable, consider draining fluids or adding fuel stabilizer to prevent breakdown during storage. Ensuring that the engine is adequately prepared for storage can save time and effort when you are ready to use it again.

Regular Start-Up Checks

When transitioning from storage to use, always inspect the engine. Check oil, fuel, and coolant levels before starting it. Conduct a thorough inspection for signs of leaks or wear after a long period of inactivity. Taking the time to perform these checks ensures that your Kubota engine is ready for operation and can perform at its best.

Conclusion

Maintaining a Kubota engine requires attention to detail, routine care, and proactive measures. The benefits of proper maintenance extend beyond the life of the engine; they enhance efficiency and safety during operation. By understanding the importance of regular checks, fluid management, and proper cleaning techniques, you can ensure that your engine remains in excellent condition.

Incorporating a structured maintenance routine helps prevent many common issues, making your experience more enjoyable and productive. Whether you utilize your Kubota engine for agricultural applications, construction, or other activities, following these tips will empower you to get the most out of your investment. With the right approach and knowledge, you can achieve longevity and efficiency in your Kubota engine, allowing it to power your adventures for years to come. Emphasizing proper care and understanding your engine’s needs ensures that you continue to enjoy the remarkable benefits that come with owning a reliable Kubota engine.