Introduction to Engine Blocks

Understanding the Engine Block

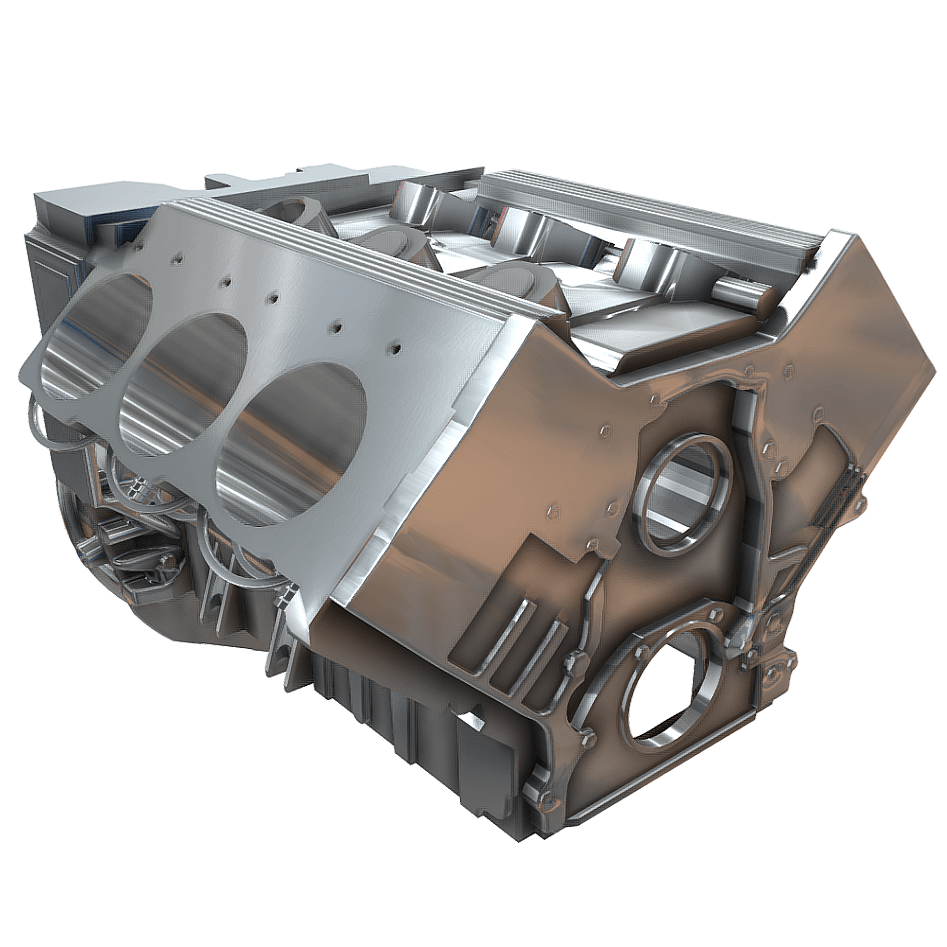

The engine block is a crucial component of any internal combustion engine. It serves as the heart of the engine, housing numerous essential parts that work together to convert fuel into motion. The engine block is typically made from cast iron or aluminum, materials chosen for their durability and heat resistance. This sturdy structure supports vital components like the pistons, crankshaft, and cylinders. Understanding the various parts of the engine block is invaluable for DIY mechanics, as it enables them to maintain, repair, and enhance their engines effectively.

The Role of the Engine Block

The primary role of the engine block is to create a rigid framework that supports the engine’s moving parts. It also plays a vital role in maintaining the engine’s integrity under extreme conditions, such as high temperatures and pressure. The engine block’s design allows for efficient airflow and fuel delivery, contributing to optimal engine performance. Knowledge of the engine block’s components equips mechanics with insight into troubleshooting problems and performing repairs.

Importance of DIY Mechanics

For DIY mechanics, developing an understanding of engine components is critical for successful repairs and maintenance. Knowledge of the engine block and its parts can facilitate a hands-on approach to engine care. With this expertise, mechanics can identify issues, perform upgrades, and implement preventive maintenance strategies. As cars become increasingly complex, mechanics who familiarize themselves with engine internals will possess a valuable skill set that enhances their DIY experience.

Key Components of the Engine Block

1. Cylinder Head

The cylinder head is an essential part of the engine block, situated at the top of the block. It houses the intake and exhaust valves, spark plugs, and in some designs, the fuel injectors. The cylinder head is a critical component as it helps regulate the airflow and combustion within the cylinders.

Functionality of the Cylinder Head

During the combustion process, the cylinder head enables the precise timing of air and fuel intake while facilitating the exit of exhaust gases. A well-designed cylinder head optimizes engine efficiency and performance. Replacement or modification of the cylinder head can lead to improved airflow, ultimately enhancing horsepower and torque. For DIY mechanics, understanding cylinder head design can provide insight into potential performance upgrades.

2. Crankshaft

The crankshaft is a pivotal element within the engine block, converting the up-and-down motion of the pistons into rotational motion that powers the vehicle. Located in the lower section of the engine block, the crankshaft is a heavy, sturdy component that withstands significant stress during operation.

Role in Engine Operation

The crankshaft connects to the pistons via connecting rods and is responsible for transferring energy to the transmission system. The smooth operation of the crankshaft is essential for the engine’s overall performance. DIY mechanics should ensure that the crankshaft is properly lubricated and balanced to avoid vibrations and premature wear. Familiarity with crankshaft maintenance and potential upgrades can significantly impact engine performance.

3. Pistons

Pistons play a fundamental role in the engine block’s operation, moving within the cylinders to create the necessary pressure for combustion. Typically made from aluminum, these cylindrical components fit snugly within each cylinder, forming a gas-tight seal.

The Combustion Cycle

The pistons are subjected to extreme conditions during the combustion cycle. They are pushed down by the explosion of the fuel-air mixture and then return to their starting position, contributing to the engine’s power delivery. For DIY mechanics, understanding piston design and movement can provide insights into issues such as compression loss or the need for replacement. Knowing how to inspect and maintain pistons is vital for optimizing engine performance.

Supporting Components of the Engine Block

1. Oil Galley

The oil galley is a network of passages within the engine block that enables the distribution of oil to various engine components. These passages are essential for lubrication and cooling, helping to reduce friction and wear during engine operation.

Essential to Engine Health

Proper oil circulation is critical for the longevity of the engine. An engine without adequate lubrication can suffer from severe damage due to overheating and friction. DIY mechanics should pay attention to oil filter changes and regular oil checks to ensure the oil galley functions effectively. Understanding its role can help in diagnosing issues related to oil pressure and lubrication.

2. Engine Block Casting

The engine block is typically manufactured using either cast iron or aluminum through a casting process. This method allows for the creation of complex shapes and internal features. The choice of material can significantly impact the engine’s weight, strength, and heat dissipation properties.

The Benefits of Different Materials

Cast iron is favored for its durability and ability to withstand high temperatures, while aluminum is lighter and better for fuel-efficient designs. Knowing the differences helps DIY mechanics in their decisions concerning upgrades or repairs. For example, when rebuilding an engine, the choice of material can affect overall performance and efficiency.

3. Cylinder Walls

The cylinder walls are critical elements within the engine block that house the pistons. These walls are designed to withstand high levels of pressure and wear during the combustion process. Properly machined and lubricated cylinder walls are essential to maintaining smooth piston operation.

Importance of Maintenance

Over time, wear can occur on the cylinder walls, leading to reduced engine performance and efficiency. DIY mechanics should regularly check for scoring or damage to the walls, which can indicate the need for a rebuild or repairs. Those familiar with the signs of wear can take proactive steps to maintain engine integrity and performance.

Repair and Maintenance Tips

1. Regular Inspections

Regular inspections of the engine block and its components are vital for maintaining vehicle health. Mechanics should check for signs of oil leaks, cracks, or other damage. Early detection of issues can prevent costly repairs down the line.

Creating a Maintenance Schedule

Establishing a routine maintenance schedule helps ensure that each component is adequately monitored. This routine may involve checking fluids, inspecting belts and hoses, and verifying the condition of the engine block. Maintaining awareness of these critical elements keeps your engine running smoothly.

2. Cleaning the Engine Block

Keeping the engine block clean is essential for optimal performance. Dirt, grime, and oil buildup can hinder performance and affect various components’ operation. Mechanics can use degreasers and brushes to clean the exterior of the engine block and maintain accessibility for inspections.

Importance of Cleaning in Troubleshooting

An organized and clean engine bay not only looks good but also allows easier identification of potential issues, such as leaks or corrosion. DIY mechanics should prioritize regular cleaning as part of their maintenance routine to ensure they have a clear view of the engine’s overall condition.

3. Understanding Repair Processes

For those interested in DIY repairs, understanding basic engine block repair processes is essential. This might include learning about resealing leaks, replacing gaskets, or rebuilding components like the cylinder head. Familiarity with these processes will empower mechanics to tackle various issues confidently.

Resources for Learning Repairs

There are numerous online resources, including videos and tutorials, that can guide DIY mechanics through different repair processes. Additionally, manuals specific to your vehicle can be invaluable in helping you understand the intricate details of engine maintenance and repair. Investing time in learning these skills can enhance your confidence and expertise.

Conclusion: Embracing Knowledge for Success

Empowering Your DIY Journey

Understanding the essential parts of the engine block and their functions equips DIY mechanics with the knowledge needed for successful maintenance and repairs. Each component plays a unique role in overall engine performance, and proper awareness can help prevent costly repairs. By gaining insights into engine internals, mechanics can more effectively troubleshoot issues and delve into repairs.

The Rewards of Maintenance and Repair

When you take the time to learn about the engine block’s components, you empower yourself to keep your vehicle running smoothly. This knowledge leads to increased confidence and satisfaction, whether you are performing routine maintenance or tackling more complex repairs. Embracing a hands-on approach to engine care not only saves money but also enhances the joy of being an engaged car owner.

Preparing for the Road Ahead

In conclusion, mastering the parts of the engine block paves the way for a fulfilling DIY experience. With the right information and techniques, you can confidently maintain and repair your vehicle, ensuring it performs at its best. As you embark on your DIY journey, enjoy the learning process and the sense of accomplishment that comes with caring for your engine. Embrace the opportunities ahead, knowing that with every repair or maintenance task, you’re enhancing both your skills and the longevity of your vehicle.