The crankshaft is one of the most critical components in an internal combustion engine. It converts the linear motion of pistons into rotational motion, driving the vehicle’s powertrain. The efficiency and performance of an engine largely depend on the quality and design of its crankshaft and its associated parts. Understanding the various crankshaft parts can help enthusiasts, mechanics, and everyday users grasp how these components contribute to engine performance. This article will break down the essential parts of a crankshaft and explore their functions and significance.

What is a Crankshaft?

1. Definition and Functionality

A crankshaft is a mechanical component that converts reciprocating linear motion into rotational motion. In an internal combustion engine, the pistons move up and down due to the combustion of fuel. The crankshaft connects to the pistons via connecting rods. Its primary role is to provide power to the engine’s flywheel and, ultimately, the vehicle’s transmission system. Because of its critical function, the crankshaft must be manufactured to high standards to ensure durability and reliability.

2. Historical Background

The history of the crankshaft dates back to the early days of mechanical engineering. It was developed as a crucial element in converting motion in steam engines. Over the years, the design of crankshafts has evolved, especially with the introduction of internal combustion engines. Modern crankshafts are made from advanced materials and engineered with precision to optimize their performance. This historical evolution has paved the way for the complex and high-performance engines we see today.

3. Importance in Engine Design

The design and construction of a crankshaft affect engine performance, smoothness, and efficiency. A well-designed crankshaft minimizes vibrations and balancing issues while ensuring optimal power output. It is vital for the crankshaft to withstand high temperatures and extreme forces. Consequently, its design holds immense importance in the overall engine development process, influencing everything from fuel efficiency to engine durability.

Key Components of a Crankshaft

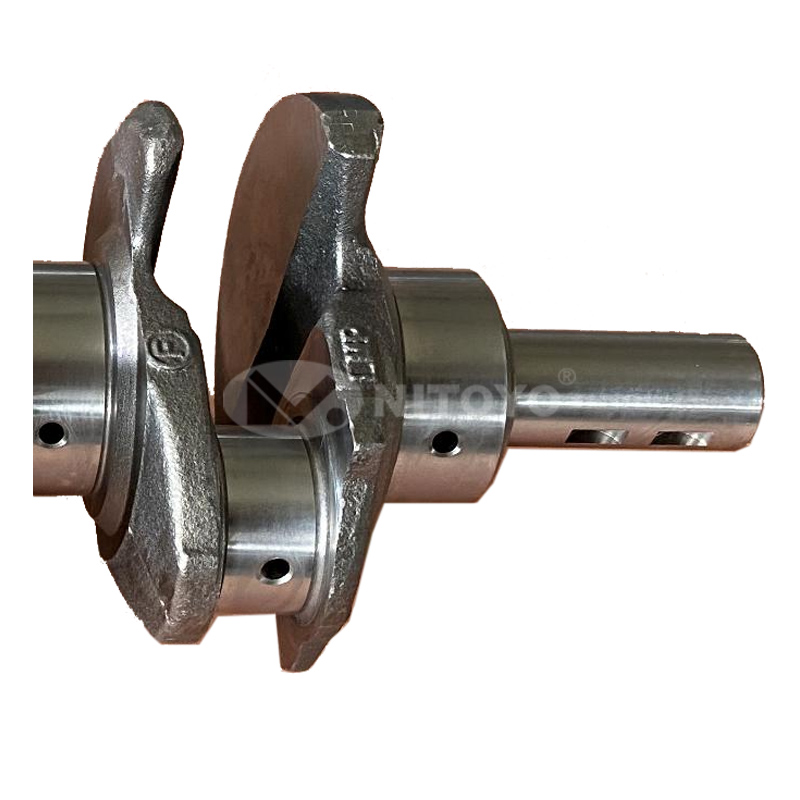

1. Main Journals

The main journals are crucial contact points of the crankshaft that are supported by the engine block. These sections bear the load of the crankshaft and help reduce friction as it rotates. The main journals are typically machined to precise tolerances to fit snugly within the engine’s main bearings. This precise fit is essential for effective oil lubrication, which helps maintain a smooth rotation and minimizes wear over time. Proper maintenance of the main journals is vital to ensure long engine life.

2. Rod Journals

Rod journals are located on the crankshaft’s arms and are where the connecting rods attach. These journals convert the linear motion of the pistons into rotational motion. The design of rod journals can significantly affect the engine’s balance and performance. Just like main journals, rod journals must be carefully machined to ensure they fit adequately with the connecting rods. If properly maintained, rod journals can help optimize engine power and efficiency.

3. Crankpins

Crankpins are the pivot points on the crankshaft where the connecting rods are attached. Each crankpin corresponds to a specific piston in the engine. Their design and placement affect how the engine generates power and how balanced the engine remains during operation. Precise machining of crankpins is essential, as even minor inaccuracies can lead to significant performance issues. The placement of the crankpins influences engine stroke and ultimately affects horsepower and torque.

Materials Used in Crankshafts

1. Steel

Steel is one of the most commonly used materials in crankshaft manufacturing. It provides excellent strength and durability, making it capable of handling the extreme forces encountered in an engine. Forged steel crankshafts, in particular, are favored for their ability to withstand higher stress levels, making them ideal for high-performance engines. The strength of steel contributes to better wear resistance and longevity.

2. Cast Iron

Cast iron is another material used for crankshaft construction. While it is generally heavier than steel, it is also very durable and resistant to wear. Manufacturers often use cast iron crankshafts in lower-performance applications, such as standard passenger vehicles. They can absorb vibrations effectively, contributing to a smoother engine operation. However, they may not offer the same performance advantages as their forged steel counterparts, particularly in high-performance scenarios.

3. Aluminum

Engine designers increasingly use aluminum in modern engine designs due to its lightweight nature. While manufacturers use aluminum crankshafts less commonly than steel or cast iron, they can find them in select applications where weight savings are critical, such as in racing or high-efficiency engines. Although engineers appreciate aluminum’s lighter weight, they recognize that it may not offer the same strength and durability as steel or cast iron, so they typically use it in specialized contexts.

The Process of Crankshaft Manufacturing

1. Forging and Machining

The manufacturing of crankshafts typically begins with forging, a process that shapes metal using high-pressure techniques to enhance its strength. Next, machinists perform precision machining on the crankshaft, where they carry out various processes to achieve the desired dimensions and tolerances. Machining ensures that each component, including journals and crankpins, is shaped correctly for optimal performance. This process is critical, as imprecise machining can lead to balance issues and compromised engine performance.

2. Surface Treatment and Finishing

Once the crankshaft has been forged and machined, it often undergoes surface treatment. This can involve processes such as hardening or coating the surface to improve wear resistance and reduce friction. Surface treatments ensure that the crankshaft can withstand prolonged use in tough environments. Machinists also perform finishing touches, such as polishing, to ensure that the crankshaft’s surfaces are smooth and capable of minimizing friction, which contributes to smoother engine performance.

3. Quality Control

Quality control is an essential aspect of crankshaft manufacturing, as any slight defect can lead to significant performance issues in the engine. Manufacturers perform quality checks at various stages of production to ensure that the crankshaft meets established specifications. This may include dimensional checks, hardness tests, and inspections for any structural defects. A rigorous quality control process guarantees that only the best crankshafts reach the market, contributing to overall engine reliability and performance.

Performance Impact of Crankshaft Designs

1. Engine Balance

The design of a crankshaft can significantly influence engine balance. A well-balanced crankshaft minimizes vibrations during operation, leading to a smoother running engine. Manufacturers consider the placement of crankpins, the overall mass of the crankshaft, and the configuration of the engine when designing a crankshaft. Improved balance results in reduced wear and tear on engine components, ultimately extending engine life.

2. Stroke Length

The stroke length of an engine directly relates to the crankshaft design. By altering the length of the crankshaft arms, manufacturers can affect the displacement of the engine. This modification can lead to changes in horsepower and torque output. Engines designed for high performance typically have a longer stroke, which allows for greater air and fuel intake. As a result, understanding how crankshaft design impacts stroke length is crucial for manufacturers aiming to optimize engine performance.

3. Power Delivery

A well-engineered crankshaft ensures efficient power delivery from the engine to the drivetrain. The connection between pistons, connecting rods, and the crankshaft significantly influences how the engine generates and transmits power. Properly aligned crankshaft components contribute to maintaining consistent torque, which translates into effective acceleration and performance. Manufacturers often refine crankshaft designs to enhance this power delivery, which is especially important for performance-focused engines.

Maintenance and Care

1. Regular Inspections

Maintaining the health of your engine includes regular inspections of the crankshaft and its parts. Over time, wear and tear can occur, so checking for signs of damage or imbalances is essential. Mechanics should look for any signs of scoring on the journals or abnormal wear on the crankpins. If you detect wear, it is essential to address these issues promptly to prevent further damage to the engine.

2. Oil Quality and Maintenance

Quality engine oil plays a vital role in maintaining the crankshaft’s integrity. Engine oil lubricates the moving parts, including the crankshaft, thereby reducing friction and wear. Regular oil changes are necessary to ensure the oil remains effective. Choosing the right oil viscosity can also impact the crankshaft’s performance, as it needs to flow well at both cold and high temperatures. Proper lubrication ultimately protects the crankshaft and enhances engine performance.

3. Professional Servicing

For optimal performance, consider having your engine serviced by a professional. Experts can conduct comprehensive checks of the crankshaft and associated components. They will evaluate the overall condition and recommend repairs or replacements if necessary. Regular professional maintenance promotes the longevity of the engine and components like the crankshaft, allowing for a smoother and more efficient operation.

Conclusion

Crankshaft parts play a fundamental role in engine performance, serving as the backbone of the internal combustion engine. Understanding the essential components and their functions helps both enthusiasts and everyday users appreciate the complexities of automotive engineering. From the main and rod journals to crankpins and various materials used in crankshaft design, each aspect contributes significantly to how an engine runs.

Investing in high-quality crankshafts ensures optimal performance, longevity, and reliability. Whether you are a car enthusiast, a mechanic, or simply someone interested in understanding how your vehicle works, knowing about crankshaft parts can deepen your appreciation for automotive engineering. Moreover, proper maintenance practices will ensure that these critical components remain in good working order.

As technology continues to advance, we can expect ongoing innovations in crankshaft design and manufacturing processes. With the focus on efficiency and performance in modern engines, the importance of crankshaft technology will continue to grow. The crankshaft is more than just a component; it is a vital part of the engine that drives the power and performance of every vehicle, making it essential for any driver to understand its significance.