Introduction: Understanding Axial Piston Pumps

Overview of Hydraulic Systems

Hydraulic systems play a crucial role in various industrial and engineering applications. They utilize fluid power to perform work, converting energy from a hydraulic fluid into mechanical energy. At the heart of many hydraulic systems is the axial piston pump. This type of pump is essential for generating hydraulic pressure, making it a vital component in machinery and equipment.

The Importance of Piston Pumps

Piston pumps, particularly axial piston pumps, offer several advantages over other hydraulic pump types. Their ability to provide high pressure and efficient operation makes them suitable for a wide range of applications. These pumps are commonly found in construction machinery, automotive systems, and other industrial applications where reliability and power are paramount. Understanding the mechanics behind these pumps is essential for those involved in the design, maintenance, and operation of hydraulic systems.

Purpose of This Article

The purpose of this article is to explore the principles of operation behind axial piston pumps and their significance in various machinery applications. We will delve into the components of an axial piston pump, how it generates hydraulic pressure, and its various uses in different fields. By the end, readers will have a comprehensive understanding of the functionality and importance of axial piston pumps in machinery.

Components of an Axial Piston

Basic Structure of the Pump

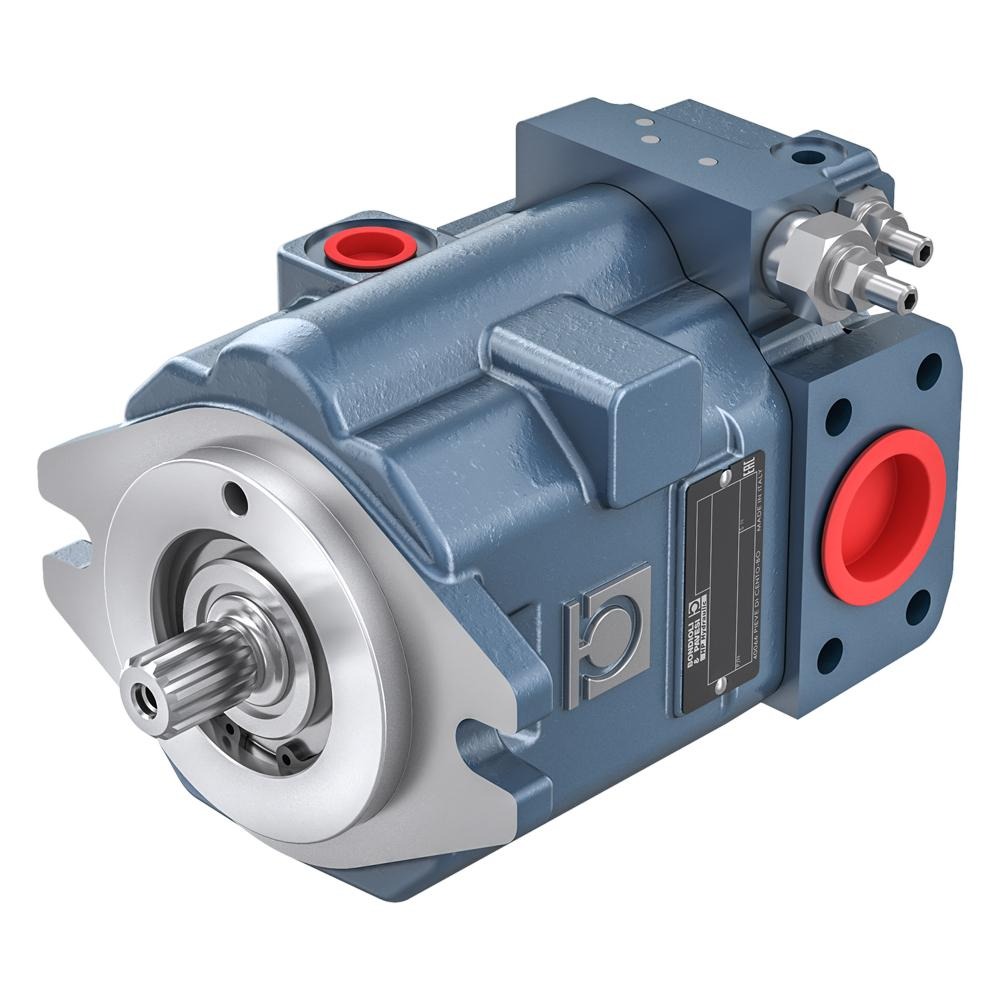

An axial piston pump consists of several key components that work together to convert mechanical energy into hydraulic energy. At the core of the pump is the cylinder block, which contains multiple cylinders arranged in a circular pattern. Each cylinder houses a piston, which reciprocates within the cylinder as the pump operates. This design allows for efficient fluid displacement and pressure generation. The axial orientation of the pistons enhances the pump’s efficiency, making it suitable for high-pressure applications.

The Role of the Swash Plate

The swash plate is another critical component in an axial piston pump. It is positioned at an angle to the cylinder block and serves as the mechanism that converts rotational motion into linear motion. When the drive shaft rotates, the swash plate causes the pistons to move in and out of their cylinders. The angle of the swash plate determines the stroke length of the pistons, directly influencing the pump’s displacement and flow rate. Adjusting the swash plate angle allows the pump to regulate pressure and flow, making it a versatile component.

Inlet and Outlet Ports

Inlet and outlet ports are essential for fluid entry and exit during the pumping process. The inlet port allows hydraulic fluid to flow into the pump, while the outlet port permits the pressurized fluid to exit. The design of these ports is vital for maintaining the flow of hydraulic fluid — if the ports are too small, they can impede the flow and efficiency of the pump. Proper engineering ensures that the inlet and outlet ports facilitate smooth and efficient fluid movement, critical for optimal pump operation.

How Axial Piston Work

The Pumping Cycle

The operation of an axial piston pump is based on a continuous cycle that involves several phases. Initially, as the swash plate rotates, the pistons extend out of their cylinders, creating a vacuum that draws hydraulic fluid in through the inlet port. This intake phase is crucial for ensuring a consistent supply of fluid.

Once the pistons reach their maximum extension, they begin to retract due to the motion of the swash plate. During this compression phase, the hydraulic fluid is pressurized as the pistons move back into the cylinder. When the pressure reaches a predetermined level, the fluid is forced out through the outlet port. This cycle repeats continuously, allowing the pump to generate hydraulic pressure efficiently.

Variability in Flow Rate and Pressure

One of the significant advantages of axial piston pumps is their ability to vary flow rate and pressure based on load demands. By adjusting the angle of the swash plate, operators can modify the stroke length of the pistons, thereby controlling the pump’s output. This feature allows axial piston pumps to adapt to changing requirements in hydraulic systems, providing optimal performance under different operating conditions.

Efficiency and Performance

Axial piston pumps are known for their high efficiency and performance. They can achieve high pressures with relatively low energy consumption, making them highly effective in various applications. The design eliminates energy loss due to friction, and the direct drive mechanism allows for smooth operation. This efficiency translates into reduced operating costs and enhanced performance, making axial piston pumps a popular choice for many industrial applications.

Applications of Axial Piston

Industrial Machinery

Axial piston pumps are widely used in industrial machinery, including hydraulic presses, forklifts, and metalworking equipment. Their ability to generate high pressure makes them ideal for powering tools that require significant force. In such applications, reliability and efficiency are paramount, and axial piston pumps deliver the necessary performance. Their compact design allows them to fit into tight spaces, making them versatile components in various machinery setups.

Automotive Systems

In the automotive industry, axial piston pumps play a critical role in hydraulic systems. They are commonly found in power steering systems, where they assist in turning the vehicle’s wheels with minimal effort. This improves driver comfort and responsiveness while enhancing vehicle performance. Additionally, axial piston pumps are utilized in braking systems, helping to modulate brake pressure for better control during stopping.

Construction Equipment

Construction equipment also benefits from the use of axial piston pumps. Excavators, bulldozers, and other heavy machinery rely on reliable hydraulic systems to perform various tasks. The high-pressure output of axial piston pumps enables these machines to lift heavy loads and operate efficiently. As the construction industry continues to evolve, the demand for powerful hydraulic systems will ensure that axial piston pumps remain integral to modern equipment.

Challenges and Maintenance Considerations

Common Issues

Despite their advantages, axial piston pumps can encounter various challenges. Common issues include cavitation, which occurs when the pressure drops below the vapor pressure of the fluid, resulting in the formation of vapor bubbles. When these bubbles collapse, they can cause significant damage to the pump components. To prevent cavitation, it is crucial to ensure that the pump operates within the specified pressure and flow ranges.

Another challenge is wear and tear on the pistons and swash plate due to continuous operation under high pressure. Over time, this wear can lead to a reduction in efficiency and performance. Regular maintenance is essential to identify and address these issues before they lead to costly repairs or equipment failure.

Maintenance Best Practices

Proper maintenance of axial piston pumps is vital for ensuring their longevity and reliability. Regular inspections should be conducted to identify wear on components and check for signs of leakage. Monitoring fluid quality is also crucial, as contaminated or degraded hydraulic fluid can damage the pump. It is essential to follow the manufacturer’s recommendations for fluid changes, ensuring optimal performance and preventing damage.

In addition to fluid quality, keeping the pump clean and free of debris will help maintain its efficiency. Periodically removing contaminants from the exterior and ensuring that the inlet and outlet ports are clear can prevent issues related to performance. By adhering to these maintenance practices, operators can prolong the life of their axial piston pumps and ensure consistent performance.

When to Seek Professional Help

While many maintenance tasks are routine and manageable, there may be times when professional assistance is necessary. If unusual noises, vibrations, or performance drops occur, it is crucial to seek help from experienced technicians. They can diagnose underlying issues, ensuring that the pump operates correctly and efficiently. Investing in professional maintenance can ultimately save time and money while extending the life of the equipment.

Future Developments in Axial Piston Technology

Innovations in Design

As technology continues to evolve, axial piston pumps are seeing advancements in design and engineering. Manufacturers are exploring ways to enhance efficiency and reduce weight while maintaining performance. Innovations such as improved hydraulic fluid formulations and advanced sealing techniques are being developed to address common challenges. These advancements ensure that axial piston pumps remain relevant in an ever-changing technological landscape.

Hybrid Systems and Energy Efficiency

With the growing emphasis on sustainability, the development of hybrid systems is gaining attention. Axial piston pumps can play a key role in integrating hybrid technology into hydraulic systems. By working alongside electric motors, these pumps can optimize energy use, significantly improving overall system efficiency. This approach aligns with global objectives aimed at reducing emissions and promoting environmentally friendly practices within the industry.

Expanding Applications

As axial piston technology advances, its applications will likely expand into new fields. Robotics, renewable energy systems, and automation are just a few areas where axial piston pumps could take on a more significant role. The flexibility and efficiency of these pumps make them suitable for a variety of applications, increasing their presence across multiple industries. The future promises exciting developments as engineers continue to innovate and push the boundaries of axial piston pump technology.

Conclusion: The Value of Axial Piston Pumps

Recognizing Their Significance

In conclusion, axial piston pumps are essential components in various machinery and equipment. Their unique design enables them to generate high pressures efficiently, offering significant advantages in performance and versatility. From industrial machinery to automotive systems, these pumps play a crucial role in ensuring smooth operations across multiple sectors.

The Importance of Regular Maintenance

Understanding the principles behind axial piston pump operation is important for maintaining their efficiency and performance. Regular inspections and maintenance can prevent common issues and extend the life of these pumps. Recognizing the signs of wear and proactively addressing them is essential for reliable operation.

Embracing Future Innovations

As the technology surrounding axial piston pump evolves, the future holds exciting possibilities. Innovations in design, energy efficiency, and expanded applications pave the way for advancements that can redefine their functional capabilities. These developments will enhance the performance of hydraulic systems while aligning with sustainability goals.

Celebrating the Journey of Engineering

Ultimately, axial piston pumps represent a marriage of engineering ingenuity and practical application. Their importance cannot be overstated, as they contribute to the efficiency and reliability of countless machines. As we look forward to future advancements, embracing this knowledge will empower us to appreciate the innovations that continue to shape the landscape of mechanical engineering. Whether in industry or daily use, axial piston pump will undoubtedly remain at the forefront of modern technology.