The crankshaft position sensor (CKP) is a vital component in modern automotive engines. It provides real-time information about the position and rotational speed of the crankshaft, which is essential for proper engine timing. A failure in this sensor can lead to significant performance issues, affecting fuel efficiency and engine power. Understanding the signs of failure and the methods for diagnosing problems with the crankshaft position sensor is crucial for vehicle owners. This article will delve into the functions of the sensor, common failure signs, diagnostic tests, and steps for replacement.

Understanding the Function of the Crankshaft Position Sensor

Role in Engine Management

The crankshaft position sensor plays a significant role in engine management systems and is key to understanding how does a crankshaft position sensor work. It collects information about the crankshaft’s position and speed, relaying this data to the vehicle’s engine control unit (ECU). The ECU uses this information to optimize ignition timing and fuel injection, ensuring the engine operates efficiently. If the sensor fails, it can disrupt these processes, leading to poor engine performance.

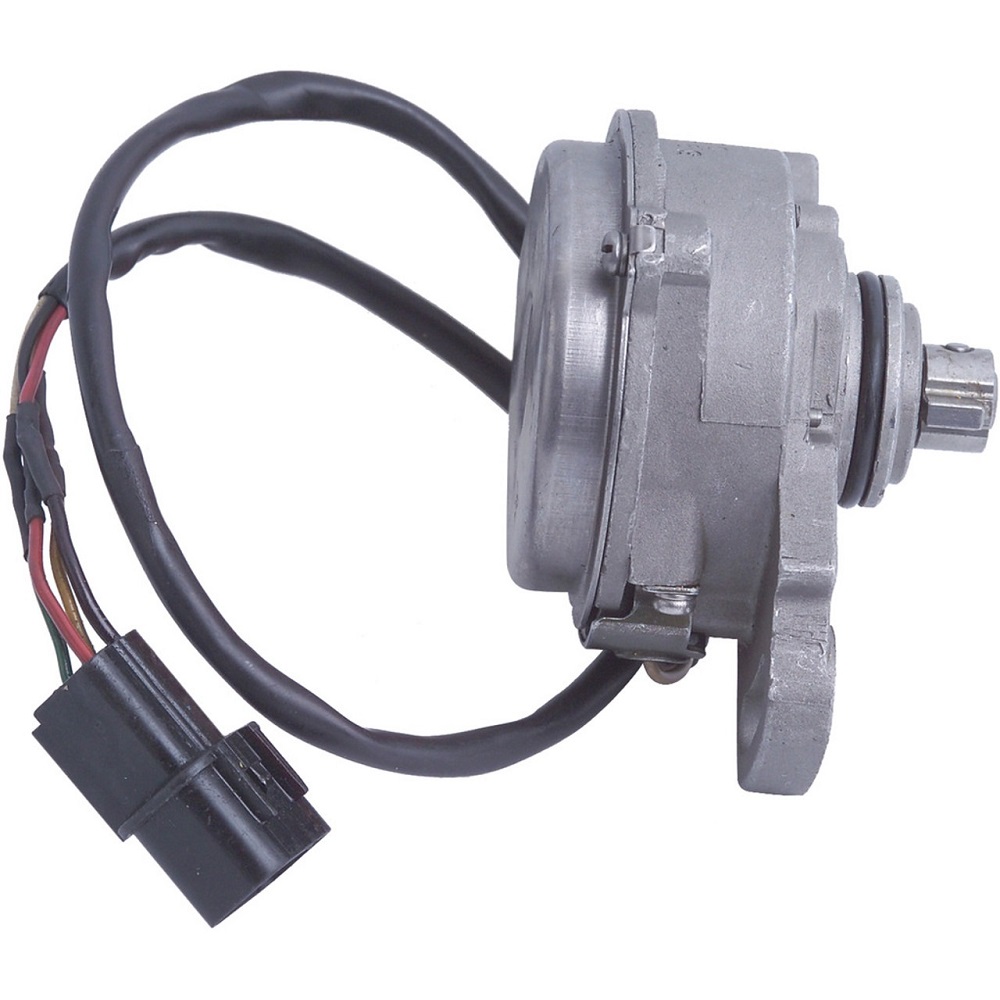

Types of Crankshaft Position Sensors

There are primarily two types of crankshaft position sensors: magnetic and hall-effect sensors. Magnetic sensors utilize a magnetic field to detect the position of the crankshaft, while hall-effect sensors use a semiconductor to detect changes in the magnetic field. Both types serve the same fundamental purpose but may vary in terms of sensitivity and output signals. Understanding which type is used in your vehicle is essential for accurate diagnosis and replacement.

Common Applications and Vehicles

Crankshaft position sensors can be found in a wide variety of vehicles, including cars, trucks, and SUVs. They are particularly important in modern vehicles equipped with advanced engine management systems. Virtually all manufacturers utilize some form of crankshaft position sensor in their automotive designs. This widespread application underscores the importance of understanding the sensor’s operation and potential failure.

Signs of Position Sensor Failure

Engine Stalling or Misfiring

One of the most noticeable signs of a failing crankshaft position sensor is engine stalling or misfiring. When the sensor malfunctions, it may send incorrect data to the ECU, causing programming errors in ignition timing. This disturbance can lead to the engine stalling unexpectedly or running unevenly. If you experience these symptoms, it is crucial to investigate the condition of your crankshaft position sensor.

Poor Acceleration

Another indicator of a faulty crankshaft position sensor is poor acceleration. If the sensor fails to provide accurate data about the crankshaft’s position, the ECU may adjust fuel delivery and ignition timing improperly. This can result in sluggish performance, making it difficult to accelerate effectively. If you notice a significant decline in acceleration responsiveness, it could point to a problem with the sensor.

Check Engine Light Activation

The check engine light on your dashboard serves as a warning system for potential vehicle issues. If the crankshaft position sensor is failing or functioning improperly, it may trigger the check engine light. It is essential to have the vehicle’s onboard diagnostics scanned for trouble codes when this light activates. Many auto parts stores offer free diagnostic scans, providing insight into the issues your vehicle may be experiencing.

Diagnosing a Failing Position Sensor

Initial Visual Inspection

The first step to diagnosing a crankshaft position sensor is conducting a visual inspection. Begin by locating the sensor, which is typically mounted on the engine block or timing cover. Examine the wiring harness for any signs of damage, corrosion, or loose connections. Ensure that the sensor is securely mounted and free from debris. A visual inspection may reveal issues that need immediate attention.

Using an OBD-II Scanner

An OBD-II scanner is a valuable tool for diagnosing issues related to the crankshaft position sensor. By connecting the scanner to your vehicle’s OBD-II port, you can retrieve stored trouble codes that indicate malfunction. Look for codes related to the crankshaft position sensor or other issues affecting engine performance. This step can help pinpoint the problem and aid in determining if the sensor needs to be replaced.

Testing Voltage and Resistance

To diagnose the crankshaft position sensor accurately, testing voltage and resistance is essential. This test involves using a multimeter to measure the sensor’s output. Start the engine and connect the multimeter to the sensor leads. Check the voltage output while the engine is running; it should match the specifications provided by the manufacturer. If the readings are significantly outside the indicated range, the sensor is likely defective.

Repairing or Replacing the Position Sensor

Considering Repair Options

In some cases, minor issues can be resolved without needing a full sensor replacement. If the wiring harness is damaged, repairs can sometimes restore functionality. Replacing damaged wires or connections may resolve sensor failure, allowing the engine to operate correctly again. Always proceed with caution and consult a professional if you are unsure about the repair process.

Steps for Replacement

If the crankshaft position sensor is faulty and requires replacement, consider the following steps:

- Gather Tools and Materials: Ensure you have the necessary tools, including a ratchet set, socket extensions, and a replacement sensor compatible with your vehicle.

- Disconnect the Battery: For safety, disconnect the negative terminal of the battery to prevent electrical issues.

- Remove the Old Sensor: Locate the sensor and carefully detach any wiring or brackets holding it in place. Use the appropriate wrench to remove the old sensor from its mounting location.

- Install the New Sensor: Position the new sensor in the same location as the old one and secure it with the required fasteners. Reconnect any wiring or brackets that were removed during the process.

- Reconnect the Battery: Once the new sensor is in place, reconnect the battery and ensure all connections are secure.

- Test the Vehicle: Start the engine and check for any warning lights on the dashboard. If the check engine light is off and the engine runs smoothly, the replacement was successful.

When to Seek Professional Help

If you experience difficulties during the testing or replacement process, it may be time to consult a professional mechanic. While some DIY enthusiasts may feel comfortable tackling these repairs, others may prefer leaving it to the experts. A qualified technician can diagnose the problem accurately and ensure a proper replacement, providing peace of mind.

Preventative Maintenance Tips

Conducting Regular Inspections

Regular inspections of your vehicle can help detect issues with the crankshaft position sensor before they become serious problems. Checking the condition of electrical components, including wiring and connectors, can help maintain optimal functionality. Additionally, regular maintenance ensures that the engine runs smoothly, reducing the strain on the sensor and prolonging its life.

Keeping the Engine Clean

Maintaining a clean engine can prevent contamination that leads to sensor malfunction. Dirt and debris can build up on the sensor, affecting its ability to provide accurate readings. Use compressed air or a soft brush to clean around the sensor without interfering with its connections.

Staying on Schedule with Routine Maintenance

Following the manufacturer’s routine maintenance schedule is essential for keeping your vehicle in peak condition. Regular oil changes, fluid checks, and parts inspections can help ensure that everything operates smoothly. Staying proactive with your vehicle’s maintenance can reduce the risk of surprises and unnecessary repairs.

Understanding the Cost of Replacement

Pricing Factors

When it comes to replacing a crankshaft position sensor, various factors influence the overall cost. The price of the sensor itself can vary significantly depending on the make and model of your vehicle. Labor costs may also differ based on the complexity of the replacement process. It is essential to gather quotes from professional mechanics to ensure an accurate understanding of expenses.

Consideration of DIY vs. Professional Replacement

If you are comfortable with DIY repairs, replacing the crankshaft position sensor on your own can save you money. However, if you lack experience, the risks associated with improper installation outweigh potential savings. Hiring a professional can guarantee peace of mind, ensuring that the sensor is installed correctly and functions as intended.

Importance of Quality Parts

When investing in a replacement sensor, consider prioritizing quality over price. Choosing an OEM (Original Equipment Manufacturer) or high-quality aftermarket part may have a higher initial cost, but it ensures reliability and durability. Quality components can prevent future issues, ultimately saving you money in the long run.

Conclusion: Prioritize Maintenance for Optimal Performance

In conclusion, the crankshaft position sensor is a crucial component to understanding your vehicle’s performance. Recognizing the signs of failure, diagnosing issues accurately, and maintaining the sensor can prolong its life. Investing in quality parts and taking preventative measures will ensure your vehicle runs smoothly.

Maintain Awareness of Crankshaft Sensor Health

Be vigilant about the health of your crankshaft position sensor. Regular inspections, proper maintenance, and timely replacements can help maintain the optimal performance of your vehicle. Awareness of potential issues allows you to address them before they escalate into more significant problems.

Engage with Professionals for Repairs

Engaging professional mechanics for complicated diagnoses and repairs can provide peace of mind. Their expertise will ensure that you receive the best service possible. When in doubt, don’t hesitate to consult a trusted technician for support regarding your crankshaft position sensor.

Enjoy the Ride

Finally, by prioritizing the condition of your vehicle’s crankshaft position sensor, you can ensure a smooth and enjoyable ride. Take pride in your vehicle’s performance and embrace the freedom of the open road. A well-maintained motorcycle or car enhances every journey, allowing you to enjoy the experience to the fullest. Embrace your adventures, knowing that you have taken the necessary steps to keep your vehicle running at its best!