The piston ring is a critical component in internal combustion engines. Often overlooked, it plays a vital role in the overall performance of an engine. By creating a vital seal between the piston and the cylinder wall, piston rings ensure that the engine operates efficiently and effectively. This article explores the importance of piston rings, their construction and types, potential issues, and maintenance tips to optimize engine performance.

Understanding the Role of Piston Rings

Functions of Piston Rings

Piston rings serve several essential functions within an engine and are vital to understanding what does a piston ring do. Their primary purpose is to create a seal between the piston and the cylinder wall, preventing the escape of combustion gases and ensuring maximum power output. Additionally, piston rings help control the engine’s oil consumption by scraping off excess oil from the cylinder walls and maintaining the proper lubrication level.

Pressure Regulation

Piston rings also play a crucial role in regulating combustion chamber pressure. By providing a tight fit, they help maintain pressure during the combustion process. Proper pressure regulation enhances engine efficiency and ensures that fuel is burned effectively. This efficiency ultimately leads to improved power delivery and better fuel economy.

Heat Transfer

Another essential function of piston rings is heat transfer. During combustion, a significant amount of heat is generated within the engine. Piston rings help dissipate this heat away from the piston to the cylinder wall. Effective heat management is crucial, as excessive heat can lead to engine knock or pre-ignition. Thus, piston rings play a vital role in maintaining optimal operating temperatures.

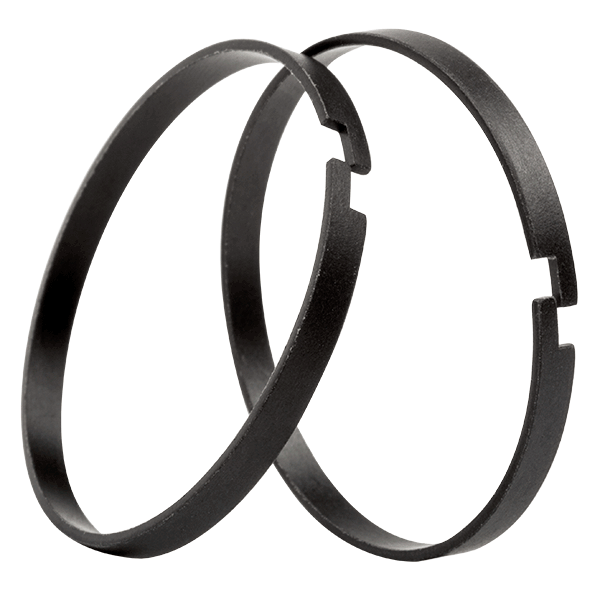

Types of Piston Rings

Compression Rings

Compression rings are the uppermost rings on the piston and serve to seal the combustion chamber. They are designed to withstand high pressure and temperatures generated during combustion. Compression rings prevent gases from escaping into the crankcase, ensuring that maximum power is delivered to the crankshaft. Made from durable materials such as cast iron or steel, these rings are designed for longevity and performance.

Oil Control Rings

Oil control rings sit below the compression rings and help regulate the amount of oil that reaches the combustion chamber. Their primary function is to scrape excess oil from the cylinder walls and return it to the crankcase. This ensures that the engine maintains proper lubrication while preventing excessive oil consumption and smoky exhaust emissions. Oil control rings are crucial for maintaining engine efficiency and longevity.

Specialty Rings

In addition to the standard compression and oil control rings, there are specialty piston rings designed for specific applications. For example, moly-coated rings provide enhanced wear resistance and reduce friction. Teflon-coated rings offer improved sealing and are commonly used in high-performance engines. These specialty rings cater to the unique demands of high-performance and modified engines, contributing to optimal performance.

Signs of Piston Issues

Excessive Oil Consumption

One of the most common signs of worn or damaged piston rings is excessive oil consumption. If you find yourself needing to add oil frequently, it could indicate that the rings are not effectively scraping oil from the cylinder walls. This situation can lead to increased oil expenditure and potential engine damage if not addressed promptly.

Blue Smoke from Exhaustg fr

Another clear indicator of pitting rings is blue smoke emanatinom the exhaust. This smoke is often a result of burning oil that has leaked into the combustion chamber due to faulty piston rings. If you notice this symptom, it’s essential to investigate further. Ignoring the problem can lead to more severe engine issues down the line.

Loss of Power and Performance

Worn piston rings can negatively impact engine performance. If you experience a sudden loss of power, sluggish acceleration, or poor fuel economy, these could be signs that the rings are no longer sealing properly. Loss of power can significantly affect the drivability of the vehicle and should not be taken lightly.

Diagnosing Piston Problems

Conducting a Compression Test

To diagnose potential issues with piston rings, a compression test is often the first step. This test measures the pressure in each cylinder during the engine’s compression stroke. If the readings are low, it may indicate that the piston rings are worn or damaged. Analyzing the compression levels can help identify the problem’s severity and lead you toward appropriate solutions.

Performing a Leak-Down Test

In addition to a compression test, a leak-down test can provide valuable information about the condition of the piston rings. This test involves pressurizing the cylinder with compressed air and measuring the rate of air loss. If air escapes from the cylinder, it could indicate that the piston rings are failing to seal properly. This test can help pinpoint the precise location of any leaks and aid mechanics in determining the next steps.

Inspecting for Other Issues

While piston ring problems may be a culprit, it’s important to consider other potential issues within the engine. Problems like worn valve seals or cylinder wall scratches can contribute to symptoms similar to those of faulty piston rings. Conduct thorough inspections to ensure that all possible causes of the problem are addressed. Left unchecked, these issues may lead to more extensive—and expensive—repairs.

Replacing Piston Rings

Assessing the Need for Replacement

If diagnostic tests indicate that your piston rings are worn or damaged, it’s important to assess the extent of the issue. In some situations, you may need to replace only the piston rings. Other cases may require a more extensive overhaul, including replacing the entire piston assembly or honing the cylinder walls. Consulting with a qualified mechanic can help determine the best course of action.

Tools and Materials for Replacement

Replacing piston rings requires specific tools and materials. Essential tools may include a socket set, torque wrench, ring compressor, and honing tool. In addition to these tools, you will need replacement piston rings and engine oil. Ensure that you have all the necessary materials on hand before beginning the replacement process.

Professional Assistance

If you are not experienced with engine work, consider seeking professional assistance for piston ring replacement. A qualified mechanic possesses the expertise to perform this task efficiently and correctly. Additionally, they can address any related issues that may arise during the replacement process, ensuring the overall health of your engine.

Preventing Piston Issues

Regular Oil Changes

One of the best proactive measures to prevent piston ring issues is to perform regular oil changes. Clean, fresh oil helps lubricate the piston assembly and prevents excessive wear. It also assists in maintaining the engine’s overall health. Follow your manufacturer’s recommendations for oil change intervals to keep your engine running smoothly.

Monitor Engine Temperature

Keep a close eye on your engine’s temperature gauge. Overheating can contribute to premature wear on engine components, including piston rings. If you notice the engine temperature rising beyond normal levels, investigate the cause and rectify it immediately. Maintaining proper engine temperature is crucial for the longevity of your vehicle.

Use High-Quality Fuel and Oil

Using high-quality fuel and engine oil can dramatically impact the health of your engine and its components. Low-quality fuel may lead to deposits and buildup in the combustion chamber, affecting the performance of piston rings. Similarly, using low-quality oil can result in inadequate lubrication, promoting premature wear. Always choose reputable products that meet your engine’s requirements.

Understanding the Cost of Replacement

Average Costs for Parts and Labor

When faced with the need to replace piston rings, understanding the costs involved is essential. The average cost of replacement parts, including piston rings and gaskets, can vary depending on the make and model of the vehicle. Additionally, labor costs at auto repair shops can range from 80to150 per hour, depending on the shop’s location and reputation.

Balancing DIY vs. Professional Help

If you have the skills necessary for a DIY replacement, you may save money on labor costs. However, if you lack experience working on engines, attempting the replacement yourself could lead to mistakes and additional expenses. Weigh the pros and cons of DIY versus professional assistance carefully before making a decision.

Long-Term Implications

Consider the long-term implications of replacing piston rings on your vehicle’s performance. Investing in high-quality parts and professional expertise may result in fewer problems in the future. Avoiding shortcuts on repairs can save you from costly issues down the line, enhancing the longevity of your vehicle.

The Future of Engine Technology

Advancements in Piston Ring Design

As technology continues to advance, we can expect developments in piston ring design and materials. Enhanced coatings may improve wear resistance and reduce friction, leading to better overall performance. Innovations focusing on efficiency and durability will likely translate into increased engine longevity and power.

Eco-Friendly Technologies

The push for eco-friendly technologies is influencing engine designs and components, including piston rings. Manufacturers are exploring options to produce more sustainable parts that contribute to lower emissions. As the automotive industry shifts toward greener technologies, new materials and processes for piston rings will emerge, aligning with environmentally friendly goals.

Smart Engine Monitoring

Modern vehicles are increasingly equipped with smart monitoring systems that track engine performance. Future engines may utilize technology that provides real-time data on piston ring health and performance, allowing drivers to receive alerts about potential issues. Such advancements will enhance preventative maintenance efforts and reduce the chances of catastrophic engine failures.

Conclusion: Prioritizing Your Engine’s Health

In conclusion, the crankshaft position sensor plays a vital role in engine performance, and the health of your engine significantly depends on each of its components—especially the piston rings. By recognizing the signs of failure, performing diagnostic tests, and maintaining your vehicle properly, you can ensure optimal performance and longevity.

Invest in Quality Parts

Selecting quality parts is essential when it comes to replacing or maintaining your engine components. When investing in piston rings, consider reputable brands known for their durability and performance. Quality parts lead to fewer problems and ultimately save money over time.

Engage with Trusted Mechanics

When in doubt, engage with trusted mechanics who can offer insights and advice on issues related to piston ring and overall engine health. Their expertise can provide peace of mind and ensure that your vehicle remains in excellent condition.

Embrace Regular Maintenance

Finally, prioritize regular maintenance for your vehicle. By staying proactive, monitoring engine performance, and caring for crucial components such as piston rings, you enhance the life of your engine. Embrace responsible vehicle ownership as you navigate every mile on the road. Your commitment to maintenance will create a smoother, more enjoyable driving experience.