When it comes to advanced engineering, few components capture the imagination and innovation of the automotive and aerospace industries like the 24 cylinder engine. This complex machine, often a marvel of design and engineering, represents the pinnacle of power and efficiency. The elaborate configuration of a 24-cylinder engine allows it to achieve remarkable performance levels, making it suitable for high-demand applications, including luxury vehicles, aircraft, and even large marine vessels. For enthusiasts and professionals alike, the intricacies and mechanics of a 24-cylinder engine offer plenty of intrigue.

The unique layout of a 24-cylinder engine allows for smooth operation and higher levels of power output compared to traditional engines with fewer cylinders. This article aims to explore the full scope of the 24-cylinder engine, including its historical development, operational mechanics, comparisons with other types of engines, and the various applications across industries. With this guide, automotive professionals, enthusiasts, and learners will better understand why this engine format continues to play a significant role in modern engineering.

The Evolution of the 24 Cylinder Engine

The journey of the 24-cylinder engine is rooted in the broader progression of engine design and automotive innovation. Understanding its evolution provides context for its current applications and designs.

Historical Context of Engine Development

The development of internal combustion engines began in the late 19th century:

- Early Innovations: Initially, automotive engines featured a limited number of cylinders, typically between two and six. As demands for performance and efficiency grew, engineers sought ways to enhance power without compromising size and weight.

- Innovative Designs: The introduction of multi-cylinder configurations marked a significant turning point. Early engines transitioned to eight or twelve cylinders, demonstrating higher performance and smoother operation.

The Shift to Larger Cylinder Configurations

The desire for more power and smoother operation led to engines with larger configurations:

- Advent of Large Capacity Engines: In the early 20th century, the emergence of larger displacement engines, featuring configurations of up to 16 cylinders, paved the way for more powerful vehicles.

- Development of the Cylinder Engine: By mid-century, innovations in design and technology allowed for the creation of engines with 24 cylinders. This configuration became particularly desirable for heavy-duty applications requiring substantial power output.

How a Cylinder Engine Works

Now that we have established the historical context, let’s delve into the mechanics of the 24-cylinder engine, exploring its components and functionalities.

Basic Configuration

The design of a 24-cylinder engine maximizes efficiency and performance through its configuration:

- V-Type or W-Type Arrangement: Many 24-cylinder engines utilize a V or W configuration. In a V engine, cylinders are arranged in two banks set at an angle to each other. A W configuration combines two V arrangements, allowing for compactness while accommodating many cylinders.

- Cylinder Layouts: A common layout includes 12 cylinders on each bank (for a total of 24), enhancing airflow and reducing weight while maintaining structural rigidity.

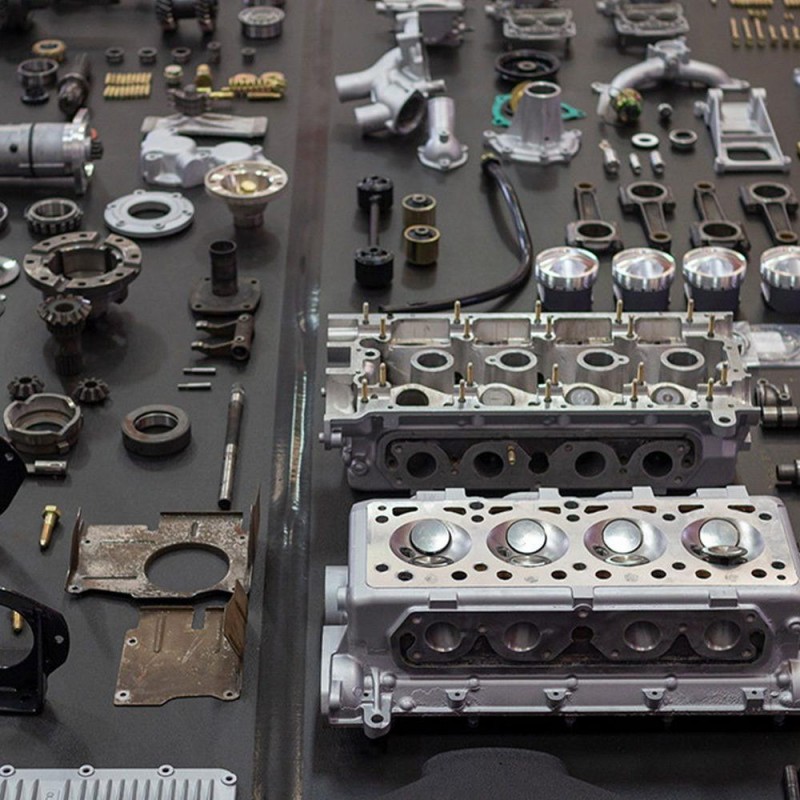

Internal Components

Understanding the internal components is crucial to grasping how a 24-cylinder engine operates:

- Pistons and Crankshaft: Each cylinder houses a piston connected to a crankshaft. As the pistons move up and down in the cylinder, they transfer energy to the crankshaft, which converts this linear motion into rotational power.

- Camshaft and Valvetrain: The camshaft operates the valves, allowing for the intake of air and fuel, as well as the expulsion of exhaust gases. In a 24-cylinder engine, the complexity of the valvetrain increases, with multiple valves per cylinder enhancing efficiency.

Fuel Injection Technologies

Efficient fuel management contributes to the performance of a 24-cylinder engine:

- Direct Fuel Injection: Many modern 24-cylinder engines use direct injection systems that inject fuel directly into the combustion chamber, promoting improved fuel atomization and combustion efficiency.

- Turbocharging and Supercharging: To boost power output without increasing engine size, manufacturers often employ turbochargers or superchargers. These technologies enhance air intake, resulting in increased horsepower and torque.

Advantages of a 24 Cylinder Engine

The enhancements and design elements of a 24-cylinder engine yield several advantages over other configurations:

Enhanced Power Output

A primary benefit of the 24-cylinder engine involves its power capability:

- High Horsepower Ratings: The synergy of 24 cylinders enables the engine to produce high horsepower ratings, making it an ideal choice for performance-oriented applications, including luxury vehicles and heavy machinery.

- Smooth Power Delivery: The balanced design of a 24-cylinder engine ensures smooth and consistent power delivery, enhancing overall driving experiences.

Improved Efficiency

Despite its size, a 24-cylinder engine can offer operational efficiencies:

- Optimal Fuel Combustion: With advanced fuel management technologies, these engines can achieve efficient fuel combustion rates. This efficiency not only translates to improved performance but also helps reduce exhaust emissions.

- Reduced Strain: A 24-cylinder engine can efficiently distribute loads among its components, ultimately leading to reduced mechanical strain. This added resilience contributes to the longevity of the engine.

Versatility in Applications

The versatility of a 24-cylinder engine allows it to be employed across various industries:

- Automotive Applications: Many luxury vehicles and high-performance cars utilize 24-cylinder engines for their seamless power delivery and cutting-edge technologies.

- Aerospace and Marine Use: Beyond automotive, 24-cylinder engines find applications in aircraft and ships, where high power and reliability are paramount.

Common Applications of the Cylinder Engine

By examining where the 24-cylinder engine is most commonly used, we can appreciate its importance in modern engineering.

Automotive Industry

The automotive industry constitutes one of the most significant markets for 24-cylinder engines:

- Luxury Cars: High-end luxury brands incorporate 24-cylinder engines in their flagship models. Automakers recognize the value that these engines bring in terms of performance, refinement, and prestige.

- Supercars and Hypercars: Manufacturers of supercars and hypercars leverage the capabilities of the 24-cylinder engine configuration to achieve unprecedented performance levels, enabling extraordinary acceleration and top speeds.

Aerospace Applications

In the aerospace sector, the demand for power and reliability drives the use of advanced engine designs:

- Aircraft Engines: Certain aircraft rely on high-performance 24-cylinder engines to propel them efficiently, particularly in large transport planes requiring substantial power generation.

- Unmanned Aerial Vehicles (UAVs): As UAV technology evolves, more advanced propulsion systems utilize efficiently-designed 24-cylinder engines for extended flight durations and improved payload capabilities.

Marine Industry

The marine sector relies on powerful engines to navigate the seas effectively:

- Large Vessels: Many large vessels, including cruise ships and cargo carriers, adopt 24-cylinder engines for their robust power characteristics. This choice allows them to maintain speed and efficiency under heavy loads.

- Yachts and Luxury Boats: High-performance yachts and luxury boats also incorporate 24-cylinder engines to achieve exceptional cruising speeds and provide smooth operation over long distances.

Challenges Associated with Cylinder Engines

While 24-cylinder engines come with advantages, they also present specific challenges that users should be aware of:

Complexity in Maintenance

The complexity of a 24-cylinder engine can lead to maintenance challenges:

- Higher Maintenance Costs: With numerous components and systems involved, maintaining a 24-cylinder engine can be costlier compared to simpler engines.

- Specialized Knowledge Required: Mechanics working on 24-cylinder engines often need specialized training and experience to navigate the intricacies of these powerful machines.

Fuel Consumption Concerns

Despite advancements in efficiency, fuel consumption remains a consideration:

- Fuel-Efficient Technologies Needed: Users of 24-cylinder engines may find fuel consumption higher than engines with fewer cylinders. Therefore, responsible driving habits and advanced fuel-efficient technologies become critical.

- Environmental Implications: With increasing awareness of environmental concerns, the dependence on high-displacement engines like 24-cylinder types raises questions about emissions and fuel sustainability.

Weight Considerations

Due to the number of cylinders and complexity involved, these engines can weigh significantly more:

- Performance Impact from Weight: The weight of a 24-cylinder engine can affect vehicle dynamics, making it essential for manufacturers to balance weight with performance capabilities.

- Design Innovations: Continued innovation in materials and engine design seeks to mitigate weight impacts while maintaining exceptional performance levels.

Future Developments in Cylinder Engine Technology

As technology continues to progress, the future of 24-cylinder engines holds promise for advancements in efficiency and performance:

Focus on Hybrid Technologies

The automotive industry increasingly leans toward hybrid technologies:

- Combining Power Sources: Future 24-cylinder engines may increasingly integrate hybrid technology, combining conventional combustion engines with electric power to enhance performance while reducing emissions.

- Electric Assist Systems: Electric motors coupled with traditional engine designs can improve acceleration and power output without over-relying on fuel consumption.

Advancements in Engine Materials

Innovations in materials engineering also promise significant changes:

- Lightweight Materials: Advances in lightweight materials, such as carbon fiber and advanced alloys, can lead to reductions in engine weight while maintaining structural integrity and performance.

- Durable High-Temperature Materials: Demands for greater performance have driven research into high-temperature materials that can withstand the rigorous conditions faced by 24-cylinder engines in various applications.

Increased Emphasis on Environmental Standards

Future developments will increasingly focus on meeting environmental standards:

- Regulatory Compliance: Manufacturers will continue to adapt to evolving environmental regulations and emissions standards by pursuing cleaner and more efficient 24-cylinder engine designs.

- Sustainability Practices: From improved manufacturing processes to sustainable materials, the trend toward environmentally-friendly practices will shape the evolution of 24-cylinder engines in years to come.

Conclusion

In conclusion, the 24-cylinder engine represents a remarkable achievement in automotive and mechanical engineering, marrying power, efficiency, and sophistication. Understanding the technical aspects, applications, and challenges associated with these engines enables us to appreciate their role in various industries. As this article has demonstrated, the evolution of the 24-cylinder engine reflects ongoing innovations designed to enhance performance while also addressing environmental and sustainability concerns.

As technology continues to advance, the future of 24-cylinder engines looks promising, offering potential developments in hybrid technologies, lightweight materials, and increased efficiency. For automotive enthusiasts, engineers, and industry professionals alike, the 24-cylinder engine remains a pivotal topic in the discourse on performance and innovation. By continuing to explore its intricacies and applications, we can better prepare for the future of engineering excellence.