Introduction: Understanding Piston Pumps

What is a Piston Pump?

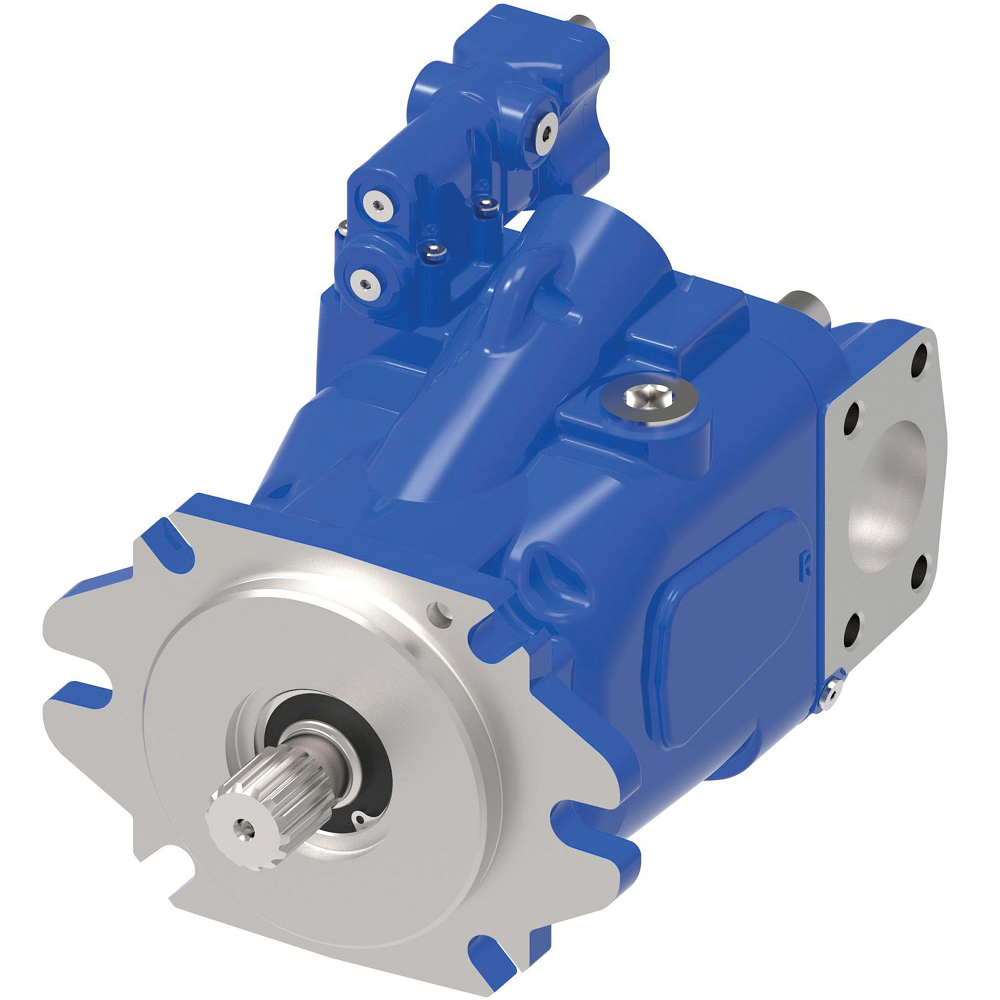

A piston pump is an essential device used in various industries for transferring fluids. Utilizing a reciprocating piston mechanism, this pump generates pressure to move liquids or gases through a system. The design allows for efficient fluid transfer, making it a popular choice for applications that require precision and reliability. Piston pumps are commonly found in automotive, industrial, and agricultural settings, where consistent and efficient fluid handling is crucial.

The Importance of Fluid Transfer

Fluid transfer is a fundamental process in many sectors, including manufacturing, agriculture, and even household plumbing. Ensuring that fluids are moved accurately and efficiently is vital for productivity and safety. Inefficient fluid transfer can lead to waste, increased costs, and potential hazards. By understanding the role of piston pumps in fluid transfer, users can make informed decisions to optimize their operations and improve overall efficiency.

Overview of Piston Pump Applications

Piston pumps are versatile and suitable for a range of applications. These pumps can handle various fluids, including water, oils, chemicals, and slurries. Industries such as food and beverage processing, pharmaceuticals, and oil and gas commonly rely on piston pumps for their fluid transfer needs. Each application requires specific features and performance characteristics, highlighting the importance of selecting the right piston pump model for the job.

Key Benefits of Piston

High Efficiency

One of the main benefits of hydraulic piston pump is their high efficiency. These pumps can generate significant pressure with minimal energy input, making them ideal for demanding applications that require consistent fluid flow. By efficiently converting mechanical energy into fluid motion, piston pumps can reduce operational costs over time. This efficiency is particularly important in industries where energy consumption directly affects the bottom line.

Versatility in Fluid Types

Piston pumps are designed to handle a wide range of fluid types, making them incredibly versatile. They can be used to transfer viscous liquids, corrosive chemicals, and even slurry mixtures without losing efficiency. This ability to manage various fluid characteristics without compromising performance makes piston pumps suitable for diverse applications across numerous industries. Users can depend on a piston pump for their fluid transfer needs, regardless of the specific requirements of the application.

Capability for High Pressure

Piston pumps are known for their ability to generate high pressure, making them suitable for applications requiring considerable force. The design of the piston allows for efficient compression of fluids, resulting in enhanced pressure output. This capability is particularly valuable in industries such as automotive manufacturing, where fluids must be delivered at high pressures for processes like hydraulic systems and fuel transfer. For anyone needing reliable high-pressure fluid transfer, piston pumps are an excellent option.

Features of Piston

Reciprocating Motion

The core feature of piston pumps is their reciprocating motion. The back-and-forth movement of the piston creates a vacuum that draws fluid into the chamber, followed by a compression stroke that forces the fluid out. This motion allows for continuous fluid transfer, enhancing operational efficiency. Modern piston pumps often employ various designs, such as single-acting or double-acting pistons, to optimize performance for specific applications. Understanding this motion is key to appreciating how piston pumps work effectively.

Adjustable Stroke Length

Many piston pumps are designed with an adjustable stroke length feature, allowing for customization of fluid delivery rates. By modifying the stroke length, operators can control the volume of fluid transferred, tailoring the pump’s performance to meet specific requirements. This adaptability is especially beneficial in applications where varying flow rates are necessary. The ability to adjust stroke lengths provides versatility, making piston pumps suitable for a wide range of tasks.

Sealing and Durability

Durability is a crucial feature that sets piston pumps apart from other types of pumps. High-quality seals and sturdy construction materials are used to ensure longevity and reliability. Piston pumps frequently include wear-resistant components that help prevent leaks and maintain performance even in demanding conditions. The robust design minimizes maintenance requirements, making piston pumps appealing for both commercial and industrial applications.

Maintenance and Care

Regular Inspections

Proper maintenance is essential to keep piston pumps operating efficiently. Regular inspections help identify potential issues before they escalate into severe problems. During inspections, it is important to check for leaky seals, wear on pistons, and the overall condition of the pump’s components. By taking a proactive approach, users can ensure their piston pumps remain in good working order and reduce the likelihood of unexpected breakdowns.

Lubrication Practices

Regular lubrication is vital for the smooth operation of piston pumps. Lubricants reduce friction between moving parts, allowing the piston to travel smoothly within the cylinder. Ensuring that the lubricant is compatible with the specific application fluid is essential for maintaining optimal performance. Users should follow the manufacturer’s recommendations for lubrication intervals and appropriate lubricant types to extend the life of the pump and enhance its efficiency.

Cleaning Procedures

Keeping piston pumps clean is another critical aspect of maintenance. Dust, dirt, and residue can build up over time, potentially affecting performance and leading to malfunctions. Regularly cleaning the exterior and accessible internal components ensures that the pump operates efficiently. Additionally, removing any fluid remnants after use can prevent contamination during future operations. Establishing a cleaning routine is key to ensuring the longevity of your piston pump.

Selecting the Right Piston

Assessing Your Needs

Before purchasing a piston pump, it is essential to assess your specific needs. Consider factors such as the type of fluid to be pumped, the required flow rate, and the pressure conditions necessary for your application. Understanding these parameters allows you to narrow down your options and select a pump that will perform effectively under your specific conditions. The more clearly you define your requirements, the easier it will be to choose the right piston pump for your needs.

Evaluating Pump Specifications

Pump specifications play a significant role in determining the right piston pump for your application. When reviewing specifications, pay attention to the maximum flow rate, pressure rating, and durability features. Ensure the selected pump meets or exceeds your requirements to guarantee optimal performance. Investing time in evaluating these specifications ensures that you choose a pump capable of handling your application efficiently and effectively.

Consulting with Experts

For those less familiar with pump mechanics, consulting with industry experts can provide valuable insights. Many manufacturers and distributors offer advice based on their experience and knowledge of piston pumps. Engaging with these professionals can help clarify any questions regarding features, specifications, or best practices for maintenance. By seeking expert guidance, you can ensure that your investment in a piston pump aligns with your specific needs and operational goals.

Advanced Technologies in Piston

Smart Pumping Systems

The evolution of technology has led to the development of smart pumping systems that integrate advanced monitoring and control features. These systems often use sensors to measure parameters such as pressure, flow rate, and temperature in real-time. Such data allows for better management of fluid transfer processes, providing alerts when conditions deviate from normal operating ranges. By incorporating smart technology, users can optimize performance and detect potential issues before they escalate, ensuring greater reliability in their operations.

Variable Speed Drives

Variable speed drives (VSD) are another advancement in piston pump technology that enhances efficiency significantly. VSD allows operators to adjust the speed of the pump motor to match the specific demand for fluid, reducing both energy consumption and wear on the equipment. This adaptability is especially beneficial in applications with fluctuating flow rate requirements. By utilizing VSD technology, businesses can enjoy cost savings on energy bills while extending the lifespan of their piston pumps through reduced strain on components.

Eco-Friendly Innovations

As environmental concerns continue to mount, piston pump manufacturers are exploring eco-friendly innovations. These developments include using sustainable materials, implementing energy-efficient designs, and creating pumps compatible with alternative fuels. Eco-friendly piston pumps can help businesses reduce their carbon footprint while maintaining performance. By investing in environmentally friendly options, companies can demonstrate their commitment to sustainability and improve their public image while continuing efficient fluid transfer operations.

Challenges and Solutions in Using Piston Pumps

Common Operational Challenges

Despite their advantages, users of piston pumps may encounter operational challenges that can hinder performance. Issues such as air entrapment in the system, cavitation, or improper setup can lead to inefficiencies and disruptions in fluid transfer. Recognizing these challenges is essential for successful operation. For instance, air entrapment can reduce efficiency; ensuring the system is purged of air before use can mitigate this issue.

Effective Solutions and Best Practices

To overcome challenges associated with piston pumps, it is essential to implement effective solutions and best practices. Regular training for personnel handling piston pumps ensures they understand the equipment’s operation and maintenance requirements. Furthermore, establishing clear protocols for pump setup, operation, and troubleshooting based on manufacturer recommendations can significantly enhance reliability. By fostering a culture of knowledge and adherence to best practices, organizations can minimize challenges and maximize the effectiveness of their pumping systems.

Addressing Wear and Tear

Over time, piston pumps can endure wear and tear, which may impact performance. Common signs include reduced flow rates, increased noise levels, or irregular pressure. Therefore, regular inspections and early intervention are necessary for addressing wear issues before they escalate. Replacing worn components and conducting periodic maintenance checks can prevent unexpected breakdowns. By recognizing and addressing wear early on, operators can ensure the long-term functionality of their piston pumps.

Conclusion: Investing in the Right Piston Pump

The Importance of Informed Decisions

In conclusion, the selection and maintenance of piston pumps are critical for efficient fluid transfer processes. Understanding the benefits, challenges, and innovative technologies available enables users to make informed decisions when choosing the right pump for their needs. With proper knowledge of their functionality, maintenance best practices, and advancements in technology, users can optimize their fluid handling systems effectively.

Long-Term Considerations

When investing in a piston pump, it is essential to consider not only the initial cost but also the long-term implications. Factors such as durability, efficiency, and maintenance costs affect the overall return on investment. By selecting a high-quality piston pump that fits your specific requirements, you can ensure reliable performance over time. This investment pays off as the pump continues to function efficiently and meets the demands of your fluid transfer needs.

Embracing Future Innovations

Looking ahead, the future of piston pumps is bright, with constant innovations aimed at improving performance and environmental impact. Embracing these advancements—such as smart technologies and energy-efficient designs—will keep your operations competitive and sustainable in an evolving market. By staying abreast of industry trends and focusing on technological improvements, you can enhance your pumping systems while contributing positively to your organization’s efficiency and environmental stewardship.

Summary

Ultimately, understanding the intricacies of piston pump and how to select and maintain them is crucial for optimizing fluid transfer operations. By prioritizing knowledge, proper care, and advancements in technology, users can ensure that their piston pumps serve them well. The journey toward efficient fluid transfer is an ongoing process that can lead to greater success and satisfaction in both personal and professional pursuits. Investing time in learning about piston pumps will empower you to make the best choices for your fluid handling needs.