The rotary engine, known for its unique design and operational characteristics, has fascinated automotive engineers and enthusiasts for decades. Unlike conventional piston engines, rotary engines, or Wankel engines, have a distinctive rotary design that offers several advantages in terms of size, weight, and efficiency. As the demand for more efficient and environmentally friendly vehicles increases, the rotary engine stands at the forefront of innovation in automotive engineering. This article will explore the principles of rotary engines, their benefits, challenges, and potential future developments in the automotive industry.

Understanding the Basics of Rotary Engines

The Wankel Engine Design

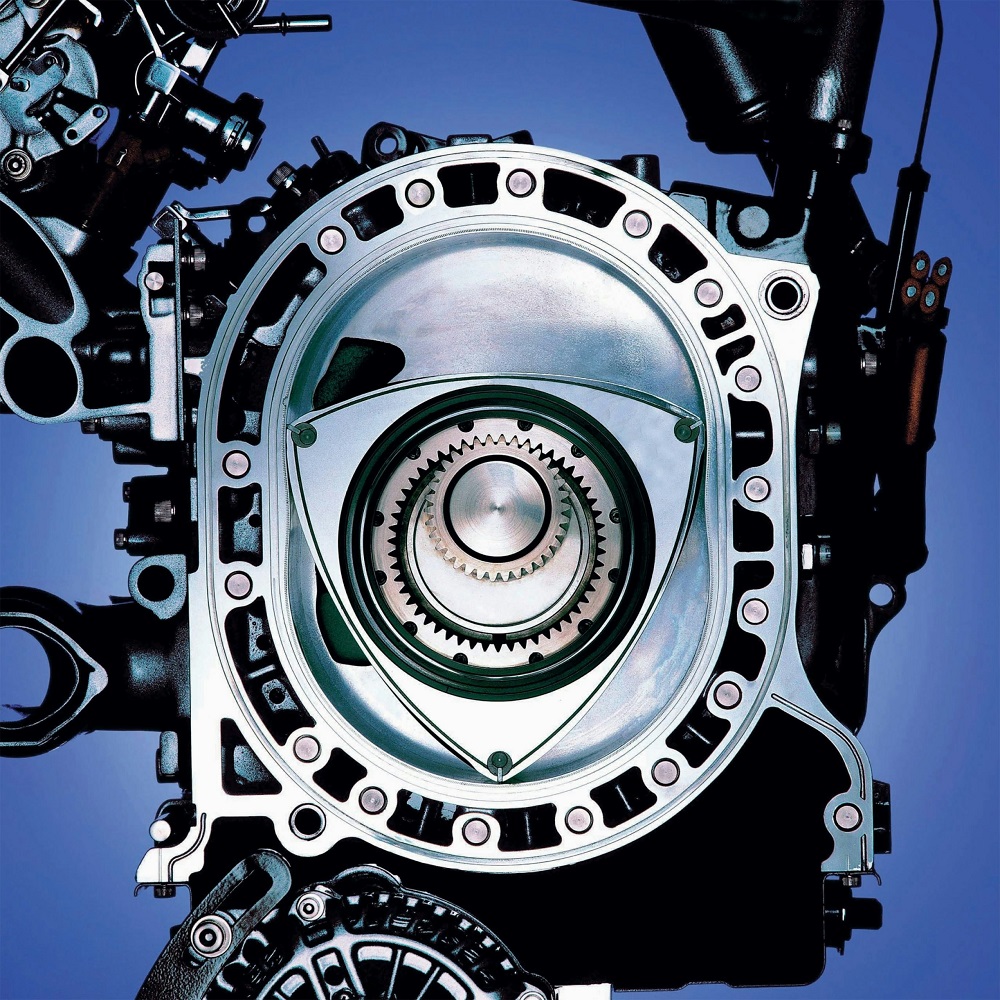

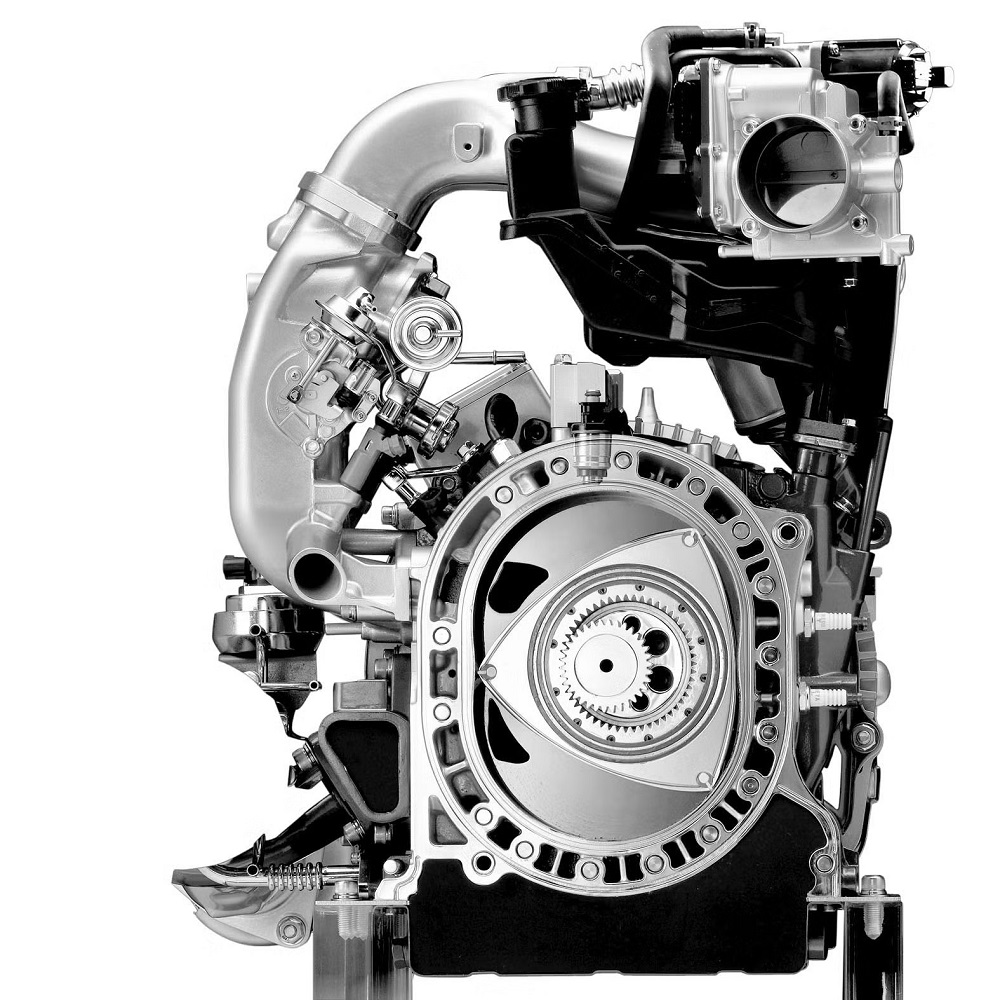

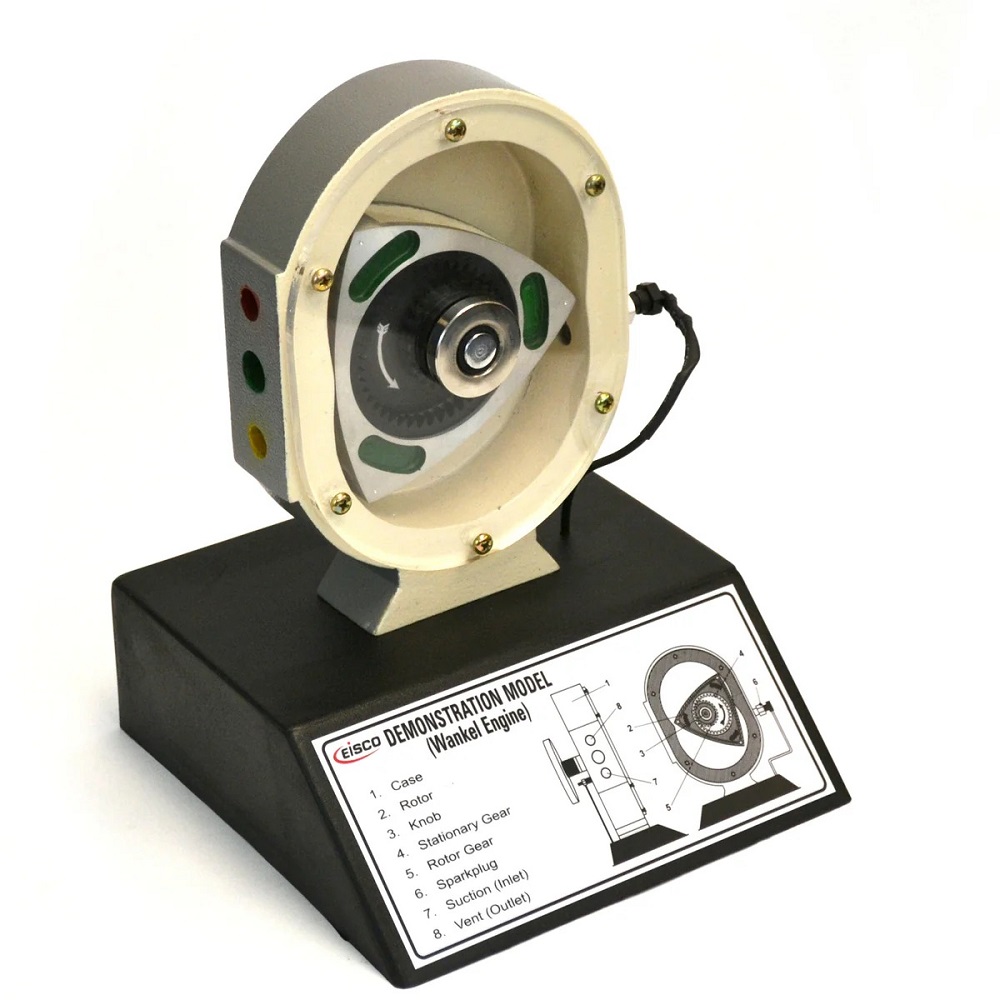

The rotary engine, or Wankel engine, is defined by its unique rotary design. Instead of using reciprocating pistons, it utilizes a triangular rotor that orbits around an eccentric shaft. This rotor moves within a near-oval housing and is responsible for the engine’s power generation. This design allows for a more compact engine configuration, making it possible to create smaller vehicles with ample power.

The operation of the rotary engine is based on the principles of combustion cycles similar to those found in conventional engines. As the rotor spins, it creates distinct chambers for intake, compression, combustion, and exhaust. The continuous rotation allows for a smoother operation compared to traditional engines, which rely on the reciprocating motion of pistons. This smoothness contributes to reduced vibration levels, enhancing overall driving comfort.

Brief History of Rotary Engines

The development of the rotary engine dates back to the early 20th century. Felix Wankel, a German engineer, patented the first rotary engine design in 1954. The innovative design saw its commercial debut in the 1960s with the launch of the NSU Spider, gaining popularity for its small size and lightweight construction. Subsequently, Mazda became the leading manufacturer of rotary engines, introducing models such as the Mazda RX-7 and RX-8.

Despite its initial success, rotary engines faced challenges in gaining widespread acceptance. Issues such as fuel efficiency, emissions, and long-term durability were concerns for both manufacturers and consumers. However, advancements in technology have led to renewed interest in the rotary engine, making it a relevant topic in contemporary automotive engineering discussions.

Comparing Rotary Engines to Traditional Engines

When comparing rotary engines to traditional internal combustion engines, several key differences arise. Rotary engines typically have fewer moving parts, which can lead to lower maintenance costs and greater reliability. Their compact design allows for different configurations and placements within vehicles, providing automotive engineers with unique design opportunities.

However, rotary engines have historically faced challenges concerning fuel efficiency and emissions. Traditional engines often have better thermal efficiencies, making them more familiar and practical for daily use. As strict emissions regulations are established, addressing these challenges is critical for the future viability of rotary engines.

The Advantages of Rotary Engines

Compact Size and Lightweight

One of the most notable advantages of rotary engines is their compact size and lightweight construction. The absence of reciprocating parts allows for a more streamlined design, translating to reduced weight. This quality makes them especially desirable for performance vehicles and motorcycles, where weight savings can lead to enhanced responsiveness and handling.

The compact nature of rotary engines also frees up space in the engine bay. Designers can create smaller vehicles or incorporate additional technology into the chassis without compromising performance. This versatility promotes innovation in design and can be a game-changer in the industry.

Smooth Operation

The operation of a rotary engine is characterized by its smoothness. Unlike traditional engines, where the firing of cylinders can lead to vibrations, rotary engines provide a continuous and even power delivery. This smooth operation enhances the driving experience, providing a sense of refinement.

Coupled with their lightweight nature, the smoothness of rotary engines offers improved handling dynamics. Riders and drivers alike appreciate the connected feel and responsiveness of vehicles powered by rotary engines. This characteristic allows for a more engaging driving experience, fostering a closer relationship between the vehicle and the operator.

Increased Power-to-Weight Ratio

Rotary engines boast an impressive power-to-weight ratio due to their lightweight construction and efficient power delivery. This make them popular for performance applications and motorsport. The rotary engine can produce significant power without adding substantial weight to the vehicle.

For racing enthusiasts, the power and efficiency of rotary engines can provide a competitive edge. Their design allows for high revs compared to traditional engines, leading to more power drawn from a smaller displacement. This characteristic becomes appealing in competitive settings, where power delivered efficiently is crucial for success.

Challenges Facing Engines

Fuel Efficiency Concerns

Despite their many benefits, rotary engines have faced criticism over fuel efficiency. Historically, rotary engines have struggled to achieve the same fuel economy as traditional piston engines. The rotary design can lead to incomplete combustion, resulting in higher fuel consumption.

Due to their lower thermal efficiency, rotary engines have been perceived as less practical for everyday use, especially as fuel prices fluctuate. Manufacturers are continually researching solutions to improve these engines’ efficiency and make them competitive with traditional engines. Addressing fuel efficiency is essential for the rotary engine’s future viability in the automotive market.

Emissions Regulations

As the automotive industry becomes increasingly stringent regarding emissions regulations, rotary engines face challenges. These engines have traditionally emitted higher levels of hydrocarbons compared to their traditional counterparts. Elevated emissions levels have raised concerns among consumers and regulators about their environmental impact.

To remain viable, manufacturers must invest in technology and innovation to reduce emissions in rotary engines. Exploring integration with hybrid or electric technologies can help enhance the sustainability of rotary engines while maintaining their performance characteristics. Adaptation to evolving standards will determine rotary engines’ future in the industry.

Market Competition

The automotive market is highly competitive, with numerous manufacturers vying for consumer attention. The dominance of conventional gasoline and diesel engines poses a challenge for rotary engines. Many consumers prefer well-established technologies that have proven reliability and efficiency.

Furthermore, advancements in electric vehicle technology have intensified the competition. The growing demand for sustainable and eco-friendly options has prompted manufacturers to invest heavily in electric and hybrid solutions. To capture market interest, rotary engines must evolve and showcase innovations that highlight their efficacy and advantages.

Future Innovations in Engines

Hybrid Technologies

Hybrid technologies represent a promising avenue for future rotary engines. By integrating a rotary engine with electric power, manufacturers can create efficient and powerful systems that cater to market demands. This hybrid approach allows for improved fuel economy and reduced emissions without sacrificing performance.

Utilizing a rotary engine as a range extender for an electric vehicle could also enhance the appeal. This configuration allows the electric motor to handle most daily driving while the rotary engine can kick in for longer trips, providing added flexibility and convenience.

Advanced Materials

The use of advanced materials can significantly influence the design and performance of rotary engines. Manufacturers may explore lightweight composites or innovative metals that enhance durability while reducing weight. These advancements will address both performance and emissions issues while allowing for more efficient energy transfer.

Incorporating heat-resistant materials can improve the reliability of rotary engines under high-stress conditions. By enhancing the durability of the engine components, the longevity and overall efficiency of rotary designs can be increased.

Robotics and Automation

As automation technology evolves, integrating robotics into the manufacturing process of rotary engines can lead to increased precision. Automated systems can enhance quality control measures and streamline production, leading to more consistent and reliable engine performance.

Additionally, building smarter systems for diagnostics and performance monitoring can help ensure owners maintain their engines correctly. Adopting advanced technologies in manufacturing can foster innovation and sustain the growth of rotary engines in the automotive space.

Embracing the Engine Community

Connecting with Enthusiasts

For fans of rotary engines, connecting with like-minded individuals can enhance your appreciation of their intricacies. Online forums and local clubs dedicated to rotary enthusiasts provide a platform for sharing insights, experiences, and technical knowledge about these engines.

Whether you are a beginner or an experienced enthusiast, engaging in these communities fosters friendships and learning opportunities. Sharing tips on maintenance, tuning, and performance can deepen your understanding of rotary designs.

Showcasing Innovations

Participating in car shows, exhibitions, or races allows rotary engine enthusiasts to showcase their customized machines and compare their builds to piston engine counterparts. Enthusiasts often display unique tuning and modification experiences, highlighting the differences in performance, design, and creativity between rotary engines and piston engines, further fueling debates such as rotary engine vs. piston engine in the automotive world.

These events provide opportunities to connect with industry professionals who can share insights about the latest developments and technologies. Staying current on innovation can enhance your passion for rotary engines and shape the future of your riding experience.

Sharing Knowledge

Consider documenting your experiences and knowledge about rotary engines through blogs or video content. Sharing tutorials, tips, and modifications can inspire others who are exploring the world of rotary engines. Engaging with your audience can help you form connections and contribute positively to the rotary community.

Being a source of knowledge and inspiration encourages more individuals to appreciate rotary technology. Your journey can motivate others to explore the potential of these innovative engines, fostering a wider interest in their applications and advancements.

Conclusion

Rotary engines represent a unique and innovative component of automotive engineering. Their lightweight design, smooth operation, and impressive power-to-weight ratios make them intriguing options for enthusiasts. By understanding innovative features, potential challenges, and future trends, you can appreciate the role of rotary engines in modern vehicles.

As the automotive landscape evolves, rotary engines must adapt to meet changing demands. By investing in new technologies, focusing on emissions reductions, and exploring hybrid possibilities, the future of rotary engines looks promising.

Engaging with the rotary community fosters connections and shared knowledge, enriching your overall experience. Whether you are a rider, mechanic, or enthusiast, embracing this technology opens a world of exciting possibilities. By exploring sustainable practices and advancements, you can share in the innovation that keeps the spirit of the rotary engine alive. Enjoy the ride, and let your passion for engineering and performance steer you toward new adventures!